What is the difference between a junction box and an outlet box?

In electrical installations, junction boxes and outlet boxes are fundamental components that often cause confusion due to their similar appearances. However, they serve distinct purposes, and using them incorrectly can lead to safety hazards such as short circuits, electrical fires, or code violations. This article will clarify the differences between these two types of boxes, explain their individual functions, and provide guidance on how to choose the right one for your needs.

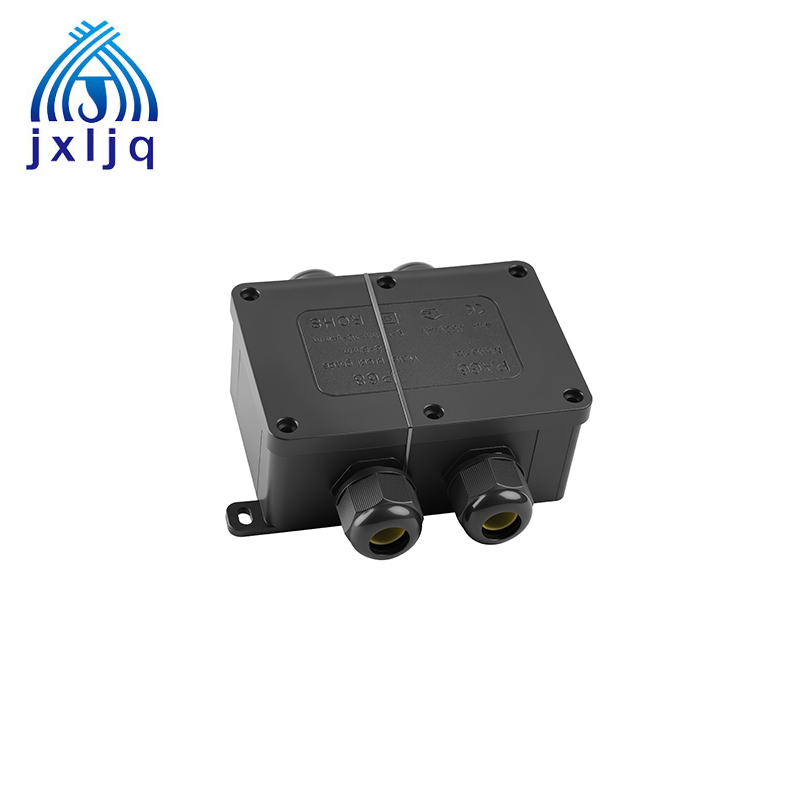

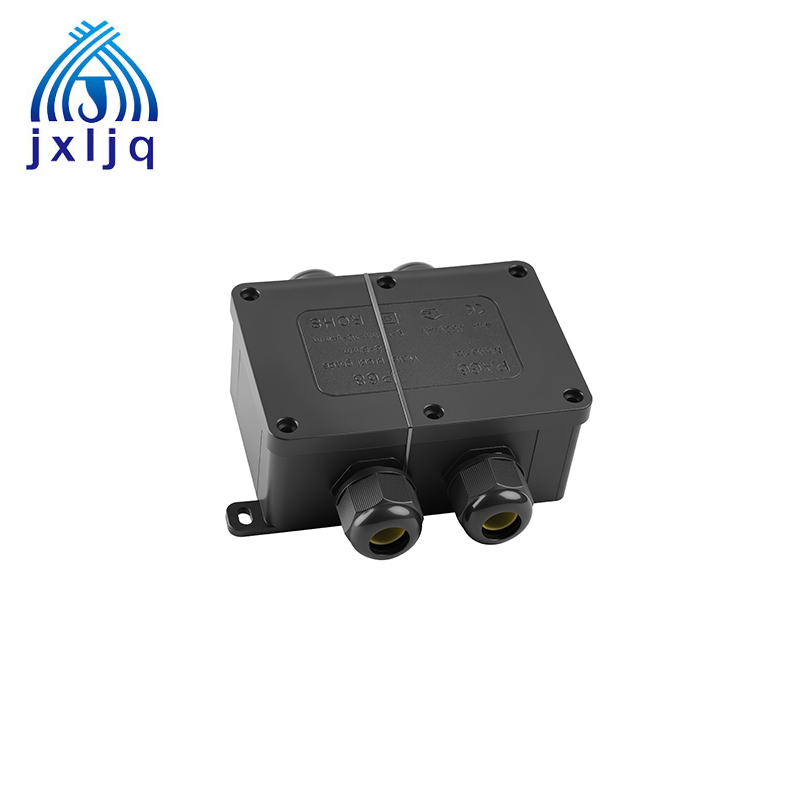

What is a Junction Box?

A junction box is a protective enclosure designed to house electrical wire connections. Its primary purpose is to safely contain and insulate wire splices, branches, or terminations, preventing accidental contact, environmental damage, or fire spread. Junction boxes are typically made of metal or plastic and come in various shapes and sizes to accommodate different wire capacities.

Key features of junction boxes include:

-

Sealed Design: They have covers that can be securely fastened to protect connections from dust, moisture, and tampering.

-

Accessibility: While often installed in concealed areas like attics or behind walls, junction boxes must remain accessible for inspection and maintenance, as per electrical codes. They do not directly host devices like outlets or switches.

-

Application: Commonly used in circuits where wires need to be joined, such as extending wiring, creating branches for multiple fixtures, or transitioning between cable types.

In summary, junction boxes act as safe hubs for wire connections, ensuring that all electrical junctions are organized and protected.

What Is an Outlet Box?

An outlet box, also known as a device box or electrical box, is specifically designed to mount and house electrical devices such as outlets, switches, or fixtures. It provides a stable point for attaching these devices and secures the wiring connections behind them. Outlet boxes are essential for maintaining structural integrity and safety in electrical installations.

Key features of outlet boxes include:

-

Device Mounting: They include built-in brackets, screw holes, or clamps to securely install outlets, switches, or other fixtures.

-

Exposure: Outlet boxes are usually installed in visible or accessible locations, such as walls, ceilings, or floors, where devices are needed for daily use.

-

Types: They vary based on application—for example, single-gang boxes for one device, double-gang for two, or specialty boxes for ceiling fans or light fixtures. Materials can be metal or plastic, with plastic being common in residential settings for non-metallic cables.

-

Function: Beyond housing devices, outlet boxes protect wire connections related to those devices and prevent heat buildup or spark exposure.

Overall, outlet boxes serve as the interface between electrical wiring and user-accessible devices, ensuring safe operation and ease of use.

Junction Box vs Outlet Box

While both boxes are crucial for electrical safety, they differ significantly in function, design, and usage. Here’s a comparative breakdown:

| Aspect | Junction Box | Outlet Box |

|---|---|---|

| Primary Function | To protect and contain wire connections (splices, junctions) without mounting devices. | To mount and house electrical devices (outlets, switches, fixtures) and their connections. |

| Typical Location | Often concealed in ceilings, walls, or crawl spaces; must be accessible but not necessarily visible. | Installed in accessible locations like walls or ceilings where devices are needed for user interaction. |

| Design Features | Focus on enclosure with a removable cover for access; may lack device-mounting hardware. | Includes device-mounting brackets, screw holes, and knockouts for cables; designed for device installation. |

| Electrical Code Requirements | Required for all wire connections to prevent fire risks; must be accessible and properly sized. | Required for all device installations; must support the device load and comply with spacing rules. |

| Common Materials | Metal or plastic, depending on environment (e.g., metal for durability, plastic for corrosion resistance). | Metal or plastic, often chosen based on cable type and location. |

| Example Use Cases | Connecting wires from multiple light fixtures, extending circuits in a basement, or splicing cables. | Installing a wall outlet for plugging in appliances, mounting a light switch, or securing a ceiling fan. |

A key distinction is that a junction box is not intended for direct device mounting—using it as an outlet box could violate codes and create safety issues. Conversely, an outlet box can sometimes contain wire connections, but its primary role is device support.

How to Choose Junction Box and Outlet Box

Selecting the right box depends on your specific electrical project. Here are practical guidelines:

1. Identify the Purpose:

Choose a junction box if you need to connect, splice, or branch wires without installing a device. Examples include adding a new circuit branch or repairing damaged wiring.

Choose an outlet box if you plan to install an outlet, switch, light fixture, or other electrical device. Ensure the box is rated for the device type.

2. Consider Material and Environment:

Metal boxes offer superior durability and fire resistance, ideal for commercial buildings or exposed areas. They are often used with metal conduits.

Plastic boxes are lightweight, corrosion-resistant, and suitable for residential wiring with non-metallic (NM) cables. Use them in dry, indoor locations.

3. Determine Size and Capacity:

Boxes must accommodate wires without overcrowding to prevent heat buildup. Calculate based on the number of wires, devices, and cable clamps.

Junction boxes: Follow National Electrical Code guidelines for cubic inch capacity—larger boxes for more connections.

Outlet boxes: Choose gang size based on the number of devices. For example, a double-gang box holds two outlets or switches.

4. Check Local Codes and Accessibility:

Always adhere to local electrical codes, which may have specific requirements for box placement, grounding, and installation.

Ensure boxes are accessible: junction boxes should have removable covers, and outlet boxes must allow easy device maintenance.

5. Consult a Professional:

If unsure, hire a licensed electrician. Improper selection can lead to hazards like electrical shocks or failed inspections.

By matching the box to your project’s needs, you ensure safety, compliance, and longevity in your electrical system.

Conclusion

While junction boxes and outlet boxes may look similar, they serve different roles in an electrical system. A junction box safely contains wire connections, while an outlet box supports and houses electrical devices. Choosing the correct box improves safety, functionality, and compliance with electrical standards.

FAQ

Q1: Can a junction box be used as an outlet box?

A: No. Junction boxes are not designed to support devices like outlets or switches. Using them as outlet boxes can lead to insecure installations, overheating, and code violations. Always use an outlet box for device mounting.

Q2: Are junction boxes and outlet boxes required to be accessible?

A: Yes, both types must be accessible per electrical codes. Junction boxes need removable covers for inspection, while outlet boxes should allow easy access for device maintenance or replacement.

Q3: How can I visually distinguish between a junction box and an outlet box?

A: Look for mounting features: outlet boxes have brackets, screw holes, or device ears for attaching outlets/switches. Junction boxes typically have a plain cover without device-mounting hardware. Also, check labeling or packaging.

Q4: What are the common sizes for these boxes?

A: Junction boxes vary by cubic inches based on wire capacity. Outlet boxes are categorized by gang size (single-gang is standard for one device, double-gang for two, etc.) and depth.