How to Size a Junction Box?

Junction boxes are critical components in electrical systems, serving as safe enclosures for wire connections. Proper sizing of a junction box is not only a requirement of electrical codes but also a fundamental safeguard against electrical hazards such as short circuits, overheating, and fires. Using an undersized junction box can lead to cramped wire routing, damaged insulation, and difficulty accessing connections for maintenance. Conversely, an oversized box may be unnecessary, increasing material and installation costs. This article will comprehensively cover what a junction box is, the key considerations for sizing, step-by-step sizing methods, a summary, and frequently asked questions to help you accurately size a junction box for any electrical project.

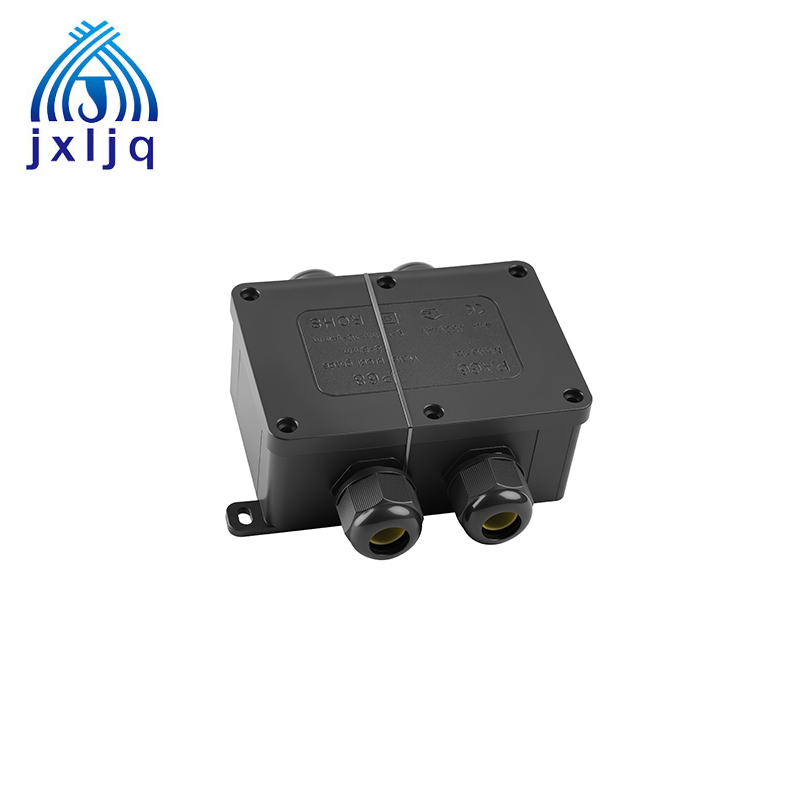

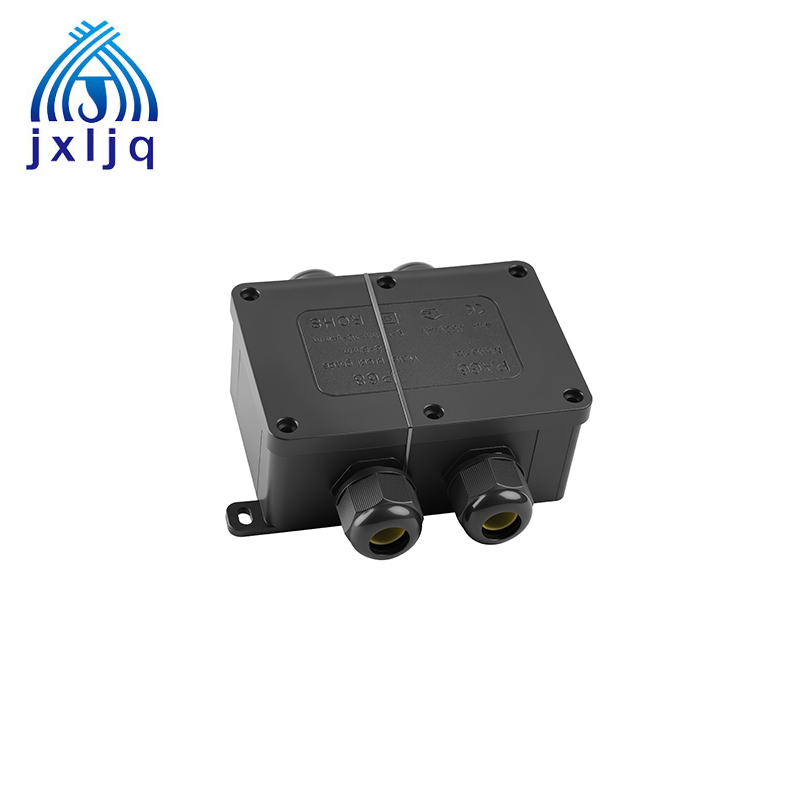

What Is a Junction Box?

A junction box is an enclosed electrical container used to house and protect wire connections, splices, and terminals. It prevents accidental contact with live wires, shields connections from dust and moisture, and reduces the risk of electrical fires.

Junction boxes are commonly made of metal or plastic and are used in residential, commercial, and industrial electrical systems. They must remain accessible after installation and comply with electrical codes such as the National Electrical Code (NEC).

Considerations When Sizing a Junction Box

Sizing a junction box requires careful consideration of several key factors to ensure compliance with electrical codes (such as the National Electrical Code, NEC, in the United States) and optimal performance. The following are the most critical considerations:

1. Number and Gauge of Conductors

The number and gauge of electrical conductors inside the junction box are the primary determinants of its size. Each conductor needs specific space for proper bending, routing, and heat dissipation. Larger gauge wires (e.g., 12 AWG vs. 14 AWG) have a larger cross-section and require more space. All conductors entering and terminating/splicing in the box must be counted, including hot, neutral, and equipment grounding conductors (EGCs).

2. Wire Bending Space

Electrical codes require sufficient bending space at conductor terminations to avoid insulation damage or reduced current-carrying capacity. The minimum bending radius, specified by manufacturers, varies by wire gauge and type (e.g., solid vs. stranded). An undersized box fails to meet this requirement, leading to stressed connections and potential electrical failures.

3. Devices and Accessories

If the junction box houses devices (e.g., switches, outlets) or accessories (e.g., wire nuts, terminal blocks), their space requirements must be considered. Each device has a specified volume requirement, provided by manufacturers or outlined in codes. For example, a standard light switch needs additional cubic inches beyond connected conductors.

4. Installation Environment

The installation environment affects box size. Outdoor/wet-location boxes must be weatherproof, with thicker walls or gaskets that reduce internal space, requiring a larger box for the same number of conductors. Corrosive environments (e.g., chemical industrial settings) may use corrosion-resistant boxes (e.g., fiberglass) with different internal dimensions, impacting sizing.

5. Electrical Code Requirements

Compliance with local and national electrical codes is mandatory. Codes specify minimum box volume based on conductor gauge/number and conductor counting rules (e.g., EGCs often count as one conductor). Non-compliance causes safety hazards, failed inspections, and legal liabilities.

How to Size a Junction Box

Sizing a junction box involves a systematic process of calculating the total space required by conductors, devices, and accessories, then selecting a box with a volume that meets or exceeds this requirement. Below is a step-by-step guide based on common electrical code standards:

Step 1: Identify and Count All Conductors

First, list all conductors that will enter the junction box and be connected (spliced or terminated) inside. Exclude conductors that pass through the box without being connected (these are called "through conductors" and may have different counting rules, depending on the code). For each conductor, note its gauge (e.g., 14 AWG, 12 AWG, 10 AWG). Then, count the conductors:.

-

Count each hot wire and neutral wire individually.

-

Count all ground wires (EGCs) as a single conductor, regardless of how many there are (this is a common NEC rule; verify with local code).

-

If the box contains a device, count the conductors connected to the device, plus any additional conductors required for the device’s space requirement.

Step 2: Determine the Space Requirement per Conductor

Electrical codes specify the minimum cubic inch (cu in) of space required per conductor based on its gauge. The following is a typical example of space requirements:

-

14 AWG: 2.0 cu in per conductor

-

12 AWG: 2.25 cu in per conductor

-

10 AWG: 2.5 cu in per conductor

-

8 AWG: 3.0 cu in per conductor

-

6 AWG: 5.0 cu in per conductor

Step 3: Calculate Total Conductor Space Requirement

Multiply the number of conductors by the space requirement per conductor (based on gauge) to get the total space needed for all conductors. For example, if you have 6 conductors of 12 AWG (4 hot, 1 neutral, 1 ground counted as 1), the total conductor space requirement is 6 × 2.25 = 13.5 cu in.

Step 4: Add Space for Devices and Accessories

If the junction box will include devices or accessories, add their space requirements to the total conductor space. Device space requirements are often specified by the manufacturer or in the code. For example, a standard single-pole switch may require 2.25 cu in (equivalent to one 12 AWG conductor). If using wire nuts or terminal blocks, check the manufacturer’s specifications for their space requirements and add accordingly.

Step 5: Select a Junction Box with Sufficient Volume

Junction boxes are labeled with their internal volume (in cubic inches). Select a box whose volume is equal to or greater than the total calculated space requirement (conductors + devices + accessories). For example, if the total calculated space is 15.75 cu in, you would select a box with a volume of at least 16 cu in (common box volumes include 10 cu in, 14 cu in, 18 cu in, 20 cu in, etc.).

Step 6: Verify Bending Space and Code Compliance

Before finalizing the box size, verify that the selected box provides sufficient bending space for the conductors (per the minimum bending radius requirements). Additionally, double-check that all calculations comply with local electrical codes, including rules for counting conductors, ground wire treatment, and device space requirements.

Summary

Sizing a junction box correctly ensures electrical safety, prevents overheating, and meets code requirements. By accounting for wire count, wire gauge, devices, and internal fittings, you can confidently select a junction box that supports safe and reliable electrical connections.

FAQ

Q1: What happens if a junction box is too small?

A box that is too small can cause wire overcrowding, overheating, insulation damage, and electrical code violations.

Q2: Can I use a larger junction box than required?

Yes. Using a larger box is generally acceptable and can make wiring and future maintenance easier.

Q3: Do ground wires count when sizing a junction box?

Yes, but all ground wires together count as one conductor for volume calculations.

Q4: Are junction box size requirements the same worldwide?

No. Requirements vary by country and region. Always follow local electrical codes and standards.

Q5: Must a junction box always be accessible?

Yes. Electrical codes require junction boxes to remain accessible for inspection, maintenance, and safety.