How to install solar connectors?

Solar connectors are essential components in photovoltaic (PV) systems, ensuring safe, stable, and efficient transmission of DC power between solar panels, cables, and other system equipment. A proper installation not only improves system performance but also prevents issues like power loss, overheating, and short circuits. This guide explains what a solar connector is, how to install it, the differences between connector types, and why Jixiang Solar Connectors are a reliable choice.

What Is a Solar Connector?

A solar connector—commonly known as an MC4 connector—is a weatherproof electrical connector used to link solar panels in residential, commercial, and industrial PV systems.

Its key features include:

-

One-way locking design to prevent accidental disconnection

-

UV, dust, and moisture resistance

-

Low contact resistance for efficient power transfer

-

Compatibility with standard solar cables

Solar connectors ensure stable DC connections, making them an indispensable part of any photovoltaic installation.

How to Install Solar Connectors

1. Prepare the Cable and Components

-

Gather tools and components: Collect solar cables, solar connectors (male-female pairs), wire stripper, crimping tool, multimeter, and safety gear.

-

Measure and cut cables: Cut solar cables to the required length based on installation layout.

-

Strip insulation: Use a wire stripper to remove ~10-12 mm of outer insulation from each cable end, exposing the copper conductor.

-

Inspect conductor: Check for fraying or damage; trim and re-strip if necessary.

2. Crimp the Terminal

-

Insert conductor: Place the exposed copper conductor fully into the terminal's wire barrel.

-

Position crimping tool: Align the tool's dies with the terminal's crimping area on the wire barrel.

-

Apply pressure: Press the crimping tool firmly until dies close, creating a tight, secure crimp.

-

Inspect crimp: Ensure the terminal is properly attached, conductor is undamaged, and no strands are loose. Replace terminal and re-crimp if faulty.

3. Assemble the Connector

-

Slide on housing: Put the connector housing over the crimped terminal and cable.

-

Orient terminal: Align the terminal correctly in the housing using the key/notch to prevent incorrect insertion.

-

Secure terminal: Push the terminal firmly into the housing until it clicks into place.

-

Lock components: Secure any locking mechanism and position rubber seal/O-ring for waterproofing.

-

Double-check assembly: Ensure all parts are correctly installed with no gaps or loose components.

4. Test and Connect

-

Perform continuity test: Set multimeter to continuity/resistance mode, touch test leads to connector terminal and cable end. A beep or low resistance indicates a good connection; troubleshoot if no continuity.

-

Connect to components: Align male-female connectors and push until locked.

-

Verify security: Gently tug cables to ensure connectors are securely locked and won't loosen.

What Are the Differences Between Connector Types?

There are several types of solar connectors available in the market, each with distinct features and applications. The main differences between them include:

-

MC4 Connectors: These are the most widely used solar connectors globally. They are single-pole connectors with a bayonet locking mechanism. MC4 solar connectors are compatible with most solar panels and systems, have a high current rating, and are designed for outdoor use with excellent weather resistance. They are easy to install and disconnect, making them suitable for both residential and commercial solar installations.

-

Tyco Solarlok Connectors: These connectors feature a push-pull locking system and are known for their high reliability and durability. They have a compact design and are suitable for use in tight spaces. Tyco Solarlok connectors have a high voltage rating and are often used in large-scale solar projects.

-

Anderson Powerpole Connectors: These are modular connectors that can be configured for different pole counts. They are commonly used in solar systems where multiple circuits need to be connected. Anderson Powerpole connectors have a high current-carrying capacity and are easy to assemble and disassemble.

-

DC Disconnect Connectors: Unlike the above-mentioned connectors, DC disconnect connectors are designed to provide a means of isolating the solar system from the DC side for maintenance or emergency purposes. They have a switch mechanism that allows the user to turn off the DC power flow. These connectors are larger in size and are typically installed between the solar panels and the inverter.

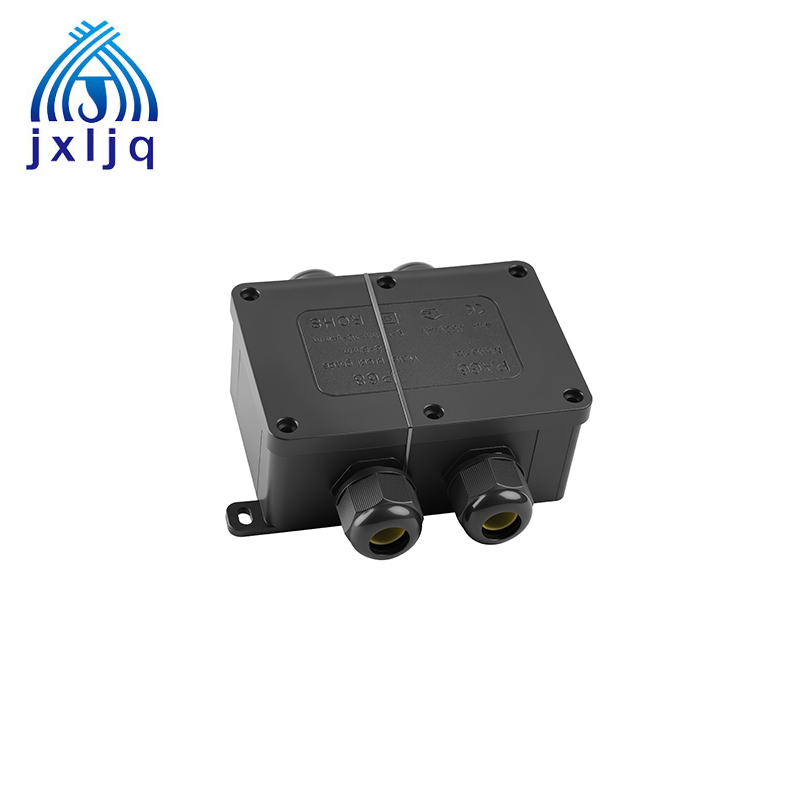

Jixiang's Solar Connectors

Brand advantages: Jixiang is a reputable manufacturer known for high quality, excellent performance, and affordability of solar connectors.

Quality & safety: Its solar connectors meet international standards and undergo rigorous testing to ensure reliability and safety.

Product range: Includes MC4-compatible connectors, which are widely used in the solar industry.

Material features: Robust housing made of high-quality materials that resist UV radiation, impact, and extreme temperatures.

Terminal performance: Terminals are made of high-conductivity copper, ensuring low power loss and efficient current transfer.

Locking mechanism: Equipped with a reliable locking mechanism for secure connection and to prevent accidental disconnection.

Applicable scenarios: Suitable for various solar applications, from residential rooftop systems to large-scale commercial solar farms; favored by installers and system integrators for easy installation and long service life.

Summary

Solar connectors play a crucial role in ensuring efficient and safe energy transmission in PV systems. By correctly preparing cables, crimping terminals, assembling connectors, and testing connections, you can significantly improve system stability and lifespan. Understanding different connector types and choosing reliable products—such as Jixiang Solar Connectors—is essential for a high-quality solar installation.

FAQ

Q: Can I mix different brands of solar connectors?

A: Not recommended, even MC4-compatible ones. Brand variations in dimensions/materials may cause power loss, overheating, or hazards. Use same-brand connectors for security.

Q: How often should I inspect solar connectors?

A: At least annually, more often in harsh environments. Check for damage, corrosion, loose connections, or overheating (discolored housing). Replace immediately if issues arise.

Q: What is the maximum voltage rating for solar connectors?

A: Varies by type. Most MC4 connectors handle 1000V-1500V DC, suitable for most systems. Choose connectors with rating matching/exceeding system voltage.

Q: Can solar connectors be installed in wet conditions?

A: Weather-resistant but best installed dry for proper sealing. If wet, dry connectors/cables thoroughly before assembly and test post-installation.