Everything You Need to Know About Cable Glands

Cable glands may seem like small components, but they play a crucial role in ensuring the safety, reliability, and performance of electrical systems. Whether used in industrial automation, telecommunications, or marine environments, these fittings are indispensable for protecting cables and maintaining system integrity. This article explains what cable glands are, how they work, their main types, and how to install them properly.

What Are Cable Glands?

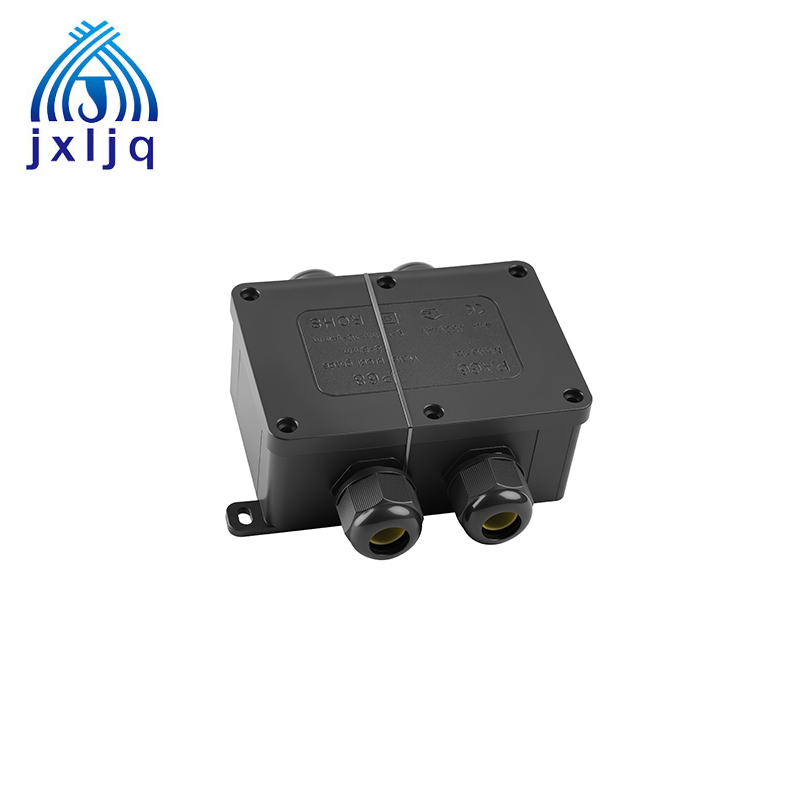

A cable gland is a mechanical device designed to attach and secure the end of an electrical cable to equipment. It provides strain relief, sealing, and protection against dust, water, and other environmental hazards. Cable glands also help maintain electrical continuity and grounding, making them essential for cable management in control panels, junction boxes, and machinery.

How Do Cable Glands Work?

Cable glands are made by combining a central enclosure or body through which cabling can pass with several attachments. These are typically a lock (or check) nut, washers, seal, attachment claw or cone, and a sealing (or compression) nut. Some models also feature two-part enclosures, tags for electrical earthing, PVC shrouding (insulation) or neoprene (rubber) sealing.

The size, arrangement and design of these vary according to the type of cable gland. Cable glands have the following principal functions:

Fixing cables in place and preventing them from being twisted or accidentally pulled out

Providing an airtight seal to keep out dust, dirt, water and moisture - a key function with electrical equipment

Fortifying the cable against strain

Protecting the vulnerable end of the cable from damage. Some also help to earth electrical cables and cut the risk of shocks and electrocution

Types of Cable Glands

There is a wide variety of cable glands designed for specific applications, cable types, and environmental conditions. Here are the five most common types:

1. Waterproof Cable Gland

Purpose: Specifically designed to prevent water and moisture ingress.

Features: Typically feature multiple sealing rings (often made of nitrile rubber or silicone) and a robust design. They are rated with high IP codes, such as IP68, meaning they are dust-tight and can be submerged in water for prolonged periods.

Applications: Outdoor lighting, marine equipment, underground cabling, and any environment exposed to rain, humidity, or washing down.

2. EMC Cable Gland

Purpose: To protect against Electromagnetic Interference (EMC/EMI).

Features: These glands have a built-in ferrite core or a special metallic mesh that filters out high-frequency electromagnetic noise. This prevents interference from disrupting sensitive electronic equipment and also contains emissions from the cable.

Applications: Data centers, telecommunications, industrial automation, and medical equipment where signal integrity is critical.

3. Explosion-proof Cable Gland

Purpose: To prevent an internal explosion from propagating outside the enclosure and igniting the surrounding hazardous atmosphere.

Features: Constructed from robust materials (often brass or stainless steel) with a specific "flamepath" design. If an explosion occurs inside the enclosure, the gland cools the hot gases as they pass through its long, narrow threads, preventing them from igniting the external area. They are certified for use in hazardous areas (e.g., ATEX, IECEx).

Applications: Oil and gas refineries, chemical plants, grain silos, and mining operations where flammable gases, vapors, or dust are present.

4. Nylon Cable Gland

Purpose: A versatile, general-purpose, and cost-effective gland.

Features: Made from durable polyamide (nylon), they are lightweight, resistant to corrosion, chemicals, and UV radiation. They are not as robust as metal glands in high-temperature or high-stress applications but are perfect for many standard industrial and commercial uses.

Applications: Control cabinets, machine wiring, and general indoor/outdoor applications where no specific hazardous conditions exist.

5. Metal Cable Glands

Purpose: For applications requiring high mechanical strength, durability, and temperature resistance.

Features: Commonly made from brass, stainless steel, or plated brass. Brass is a good all-rounder, while stainless steel (typically 316 grade) offers superior corrosion resistance for harsh environments like food processing, marine, or offshore platforms.

Applications: Heavy industry, outdoor applications with high physical stress, and corrosive environments.

How to Install a Cable Gland

Proper installation is essential to ensure effective sealing and strain relief. Here’s a step-by-step guide:

1. Select the right gland size and material according to the cable diameter and environmental conditions.

2. Prepare the cable by stripping the outer sheath without damaging the inner insulation or shielding.

3. Insert the cable through the gland components — usually the sealing nut, clamping ring, and main body.

4. Tighten the gland body into the enclosure or junction box using a locknut.

5. Secure the sealing nut to compress the rubber seal around the cable, ensuring a tight and watertight fit.

6. Inspect the installation to confirm proper sealing and strain relief.

Conclusion

Cable glands are small but powerful components that protect electrical systems from environmental hazards and mechanical stress. From waterproof and nylon types to EMC and explosion-proof designs, each type serves a specific purpose to ensure safety and reliability. By understanding how cable glands work and how to install them correctly, you can significantly improve the performance and longevity of your electrical installations.