What is the use of nylon cable gland?

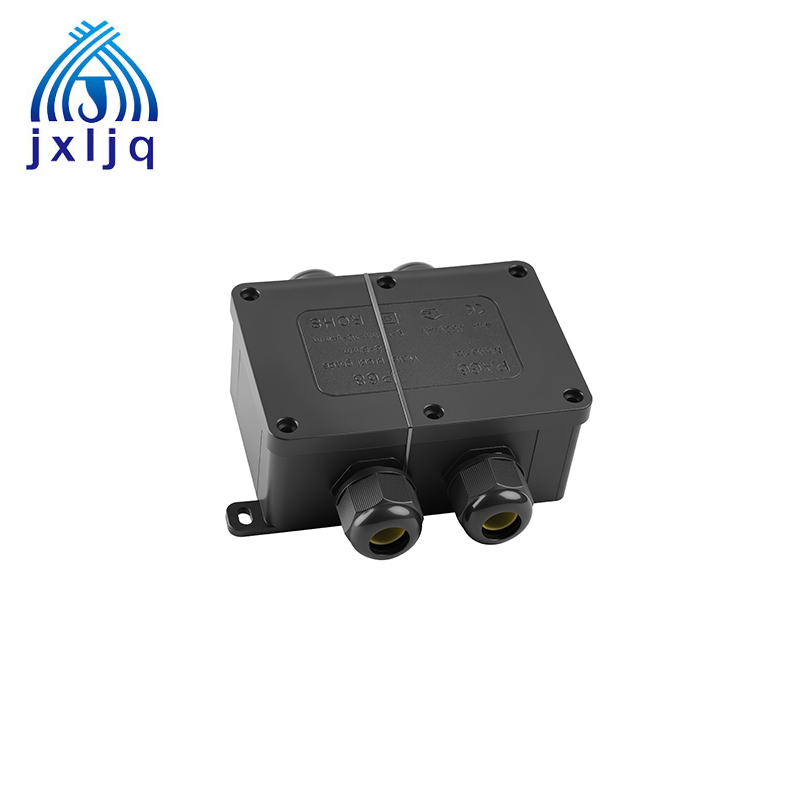

In the intricate world of electrical and electronic installations, ensuring the integrity, safety, and longevity of cable runs is paramount. Wherever a cable passes through an enclosure, panel, or machine wall, a critical vulnerability exists. This is where the humble yet indispensable nylon cable gland steps in. More than just a hole plug, it serves multiple vital functions.

1. Securing and Sealing:

The primary purpose of any cable gland, including those made from nylon, is twofold:

Securing (Strain Relief): It firmly clamps onto the cable's outer sheath. This prevents external forces (pulling, twisting, vibration) from being transmitted directly to the delicate internal wires and their termination points inside the enclosure. This "strain relief" is crucial for preventing wire breakage, loose connections, and potential short circuits or fires.

Sealing (Environmental Protection): It creates a tight seal around the cable and against the entry hole in the enclosure. This barrier protects sensitive internal components from:

Dust and Dirt: Preventing contamination that can cause abrasion, insulation breakdown, or interference.

Moisture and Liquids: Crucial for outdoor use, washdown areas (food processing), marine applications, and general humidity protection. The effectiveness is measured by its IP (Ingress Protection) rating (e.g., IP68 for complete dust-tightness and protection against prolonged submersion).

Gases: In specific hazardous environments.

EMI/RFI Shielding (in shielded variants): Specialized nylon glands with metallic elements maintain the continuity of a cable's braided shield, protecting signals from electromagnetic or radio frequency interference.

2. Material Properties

Nylon (polyamide) is the core material for cable glands due to its exceptional balance of mechanical and chemical properties:

High Strength and Durability: Nylon PA66 (UL94V-2 fire-rated) offers superior tensile strength and impact resistance, ensuring long-term performance in harsh environments.

Chemical Resistance: It resists corrosion from acids, alkalis, salts, and solvents, making it ideal for use in chemical plants, oil refineries, and outdoor settings.

Temperature Stability: Nylon glands operate reliably in extreme temperatures, from -40°C to 100°C (static) or -20°C to 50°C (dynamic), with some variants enduring short-term peaks up to 160°C.

Lightweight and Cost-Effective: Compared to metal glands, nylon is lighter and more economical, reducing installation effort and material costs.

Electrical Insulation: Nylon’s inherent dielectric properties prevent electrical leakage, enhancing safety in high-voltage applications.

3. Applications

Nylon cable glands are versatile and widely used across industries:

Industrial Automation: Securing cables in machinery, control panels, and robotics, where resistance to oil, grease, and vibration is critical.

Marine and Offshore: Protecting cables on ships, offshore platforms, and underwater equipment from saltwater corrosion and submersion.

Construction and Infrastructure: Ensuring waterproof connections in lighting systems, HVAC installations, and fire alarm networks.

Automotive and Transportation: Securing wiring in vehicle engines, EV charging stations, and railway systems, where weight reduction and oil resistance are priorities.

Renewable Energy: Safeguarding cables in wind turbines, solar panels, and hydroelectric systems exposed to UV radiation and extreme weather.

4. Types of Nylon Cable Glands

Nylon cable glands come in various designs to suit different needs:

Straight/Right-Angle Glands: Straight glands allow direct cable entry, while right-angle versions facilitate installation in confined spaces or around corners.

Explosion-Proof Glands: These meet stringent safety standards (e.g., IEC 60079-7) for hazardous environments, such as oil rigs or chemical plants.

Torsion resistant Glands: Feature spiral locking mechanisms to prevent cable twisting in mobile equipment like cranes or robotics.

Heavy-Duty Glands: Constructed with reinforced PA66 and thicker seals for high-pressure or deep-sea applications.

Threaded Variants: Available in metric (M), PG (German), NPT (American), or G (British) threads to match international standards.

Conclusion

Nylon cable glands are indispensable for securing and protecting cables in diverse industries. Their robust material properties, reliable sealing, and adaptability to various environments make them a cost-effective choice. By understanding their types and regulatory classifications, engineers and manufacturers can optimize cable management systems for safety and efficiency. Whether in harsh industrial settings or everyday electrical applications, nylon cable glands ensure seamless and durable connections.