What is the function of waterproof cable connector?

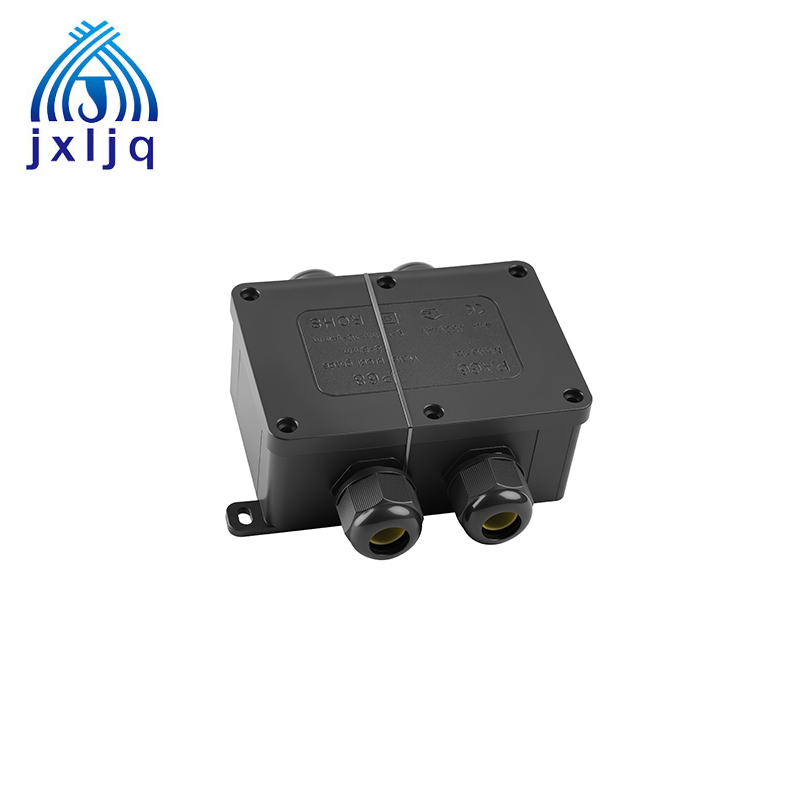

Waterproof cable gland is a cable connection device specially designed to provide excellent waterproof performance in humid or outdoor environments. According to their different materials and structures, waterproof cable joints can be divided into many types, such as brass nickel-plated metal cable waterproof joints, stainless steel cable waterproof joints, and nylon waterproof joints.

These connectors are usually made of corrosion-resistant materials and have special waterproof designs to ensure the reliability and safety of cable connections. The main functions of waterproof cable joints are as follows:

1. Waterproof protection: The most significant function is to prevent water, moisture and other liquids from penetrating into the cable connection, avoid moisture or short circuit inside the cable, and protect the integrity and safety of the cable connection. This is especially important for cables that are used outdoors, in humid environments, underwater, or in chemically corrosive environments.

2. Ensure connection stability: Through its unique structure and material design, the waterproof cable joint can firmly connect cables to ensure the stability and reliability of the connection. This helps reduce power outages or signal transmission issues caused by loose or dislodged connections.

3. Improve safety: The use of waterproof cable joints can reduce safety risks such as electrical fires and electric shocks caused by moisture, corrosion or short circuits at cable connections. They provide an extra layer of security to power systems, protecting workers and equipment.

4. Extend the service life of cables: Waterproof cable joints help extend the service life of cables by protecting them from moisture and other harmful substances. This reduces the frequency of repairs or replacements due to cable damage, reducing maintenance costs.

5. Adapt to harsh environments: Waterproof cable joints are designed to work in harsh environmental conditions, such as high temperature, low temperature, high humidity, and highly corrosive places. They have good weather and corrosion resistance and are able to maintain stable performance in these environments.

6. Simplified installation and maintenance: Some waterproof cable connectors feature easy-to-install designs that allow cable connections to be completed quickly and easily. At the same time, their water-resistant properties also help reduce maintenance, as fewer repairs are needed due to joint failure.

In summary, waterproof cable joints play a vital role in power systems. They provide waterproof protection, ensure connection stability, improve safety, extend cable service life, and adapt to harsh environments. Stable operation provides strong support.