What is the difference between a cable gland and a conduit gland?

In electrical and instrumentation installations, ensuring safety, environmental protection, and mechanical security is paramount. Cable glands and conduit glands (often called conduit fittings or connectors) are essential components for achieving this, but they serve distinct purposes. Understanding their differences is critical for proper system design and installation.

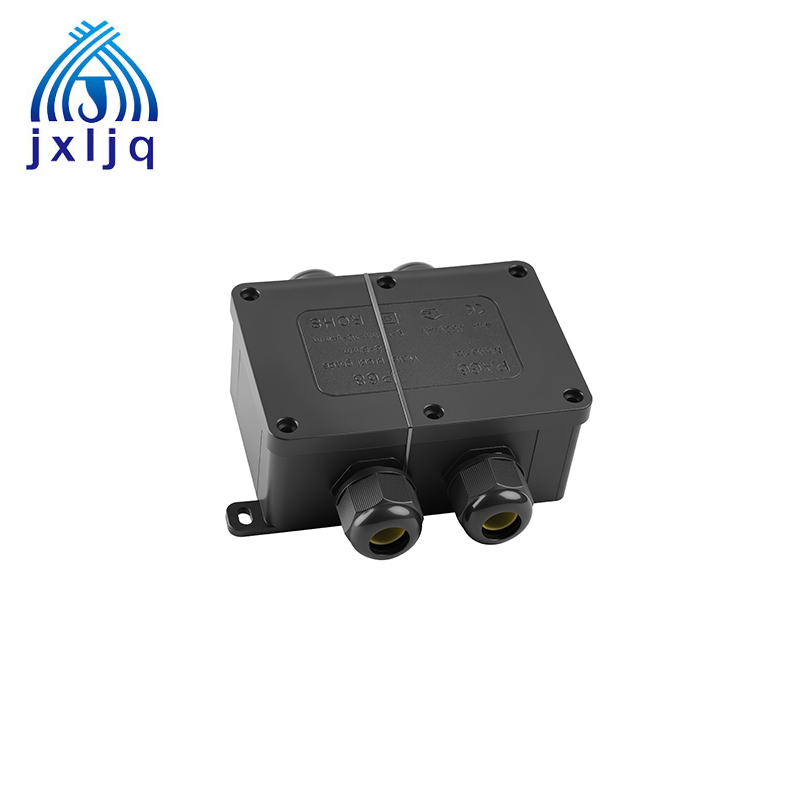

I. Cable Gland

Function:

-

To securely attach and seal the end of an electrical cable where it enters an enclosure, panel, machine, or junction box.

-

To provide strain relief, preventing the cable from being pulled out or twisted, protecting the internal electrical connections.

-

To maintain the ingress protection (IP) rating or explosion-proof integrity of the enclosure by sealing against dust, dirt, moisture, and sometimes gases.

Purpose:

-

Protection: Shields electrical connections inside enclosures from environmental contaminants (water, dust, chemicals).

-

Safety: Prevents cable pull-out, reducing the risk of short circuits, arcing, or equipment damage. Essential for safety in hazardous areas (ATEX/IECEx).

-

Sealing: Maintains the environmental seal of the enclosure.

-

Grounding/Bonding: Many glands provide continuity of the cable armor or braid to the enclosure for earth grounding (especially armored cable glands).

Examples:

-

Sealing a power cable entering a control panel in a factory.

-

Attaching an instrumentation cable to a sensor housing outdoors.

-

Securing an armored (SWA) cable to a motor terminal box.

-

Connecting a data cable to a junction box on an offshore platform.

II. Conduit Gland (Conduit Fitting/Connector)

Function:

-

To securely attach and seal the end of a rigid or flexible conduit run to an enclosure, panel, or junction box.

-

To provide a mechanical connection point between the conduit and the enclosure.

-

To protect the wires or cables inside the conduit from damage (abrasion) as they pass through the entry point.

-

To maintain the ingress protection (IP) rating or explosion-proof integrity of the entire conduit system at the entry point.

Purpose:

-

Conduit Termination: Provides a robust and secure end point for conduit runs.

-

System Sealing: Seals the interface between the conduit and the enclosure, preventing contaminants from entering the conduit system or the enclosure.

-

Protection: Protects wires inside the conduit from sharp edges at the entry hole.

-

Grounding Continuity: Ensures electrical continuity between metallic conduit and the enclosure for grounding (especially with metal conduit and fittings).

Examples:

-

Connecting a run of EMT (Electrical Metallic Tubing) conduit to a main distribution panel.

-

Attaching a flexible liquid-tight conduit to a machine control cabinet.

-

Terminating rigid steel conduit entering an explosion-proof junction box in an oil refinery.

-

Securing PVC conduit to an outdoor lighting fixture enclosure.

III. Key Differences Summarized

| Feature | Cable Gland | Conduit Gland (Fitting) |

|---|---|---|

| Seals Around | The individual cable(s) itself. | The conduit tube (rigid or flexible). |

| Primary Job | Secure/seal cable entry. Strain relief. | Secure/seal conduit entry. Protect wires. |

| What it Holds | The cable jacket/armor. | The conduit itself. |

| Protects | Internal enclosure connections from the environment via the cable entry. | Wires inside the conduit from abrasion at the entry point. Seals the conduit system. |

| Strain Relief | Yes, directly on the cable. | No, primarily on the conduit. The conduit provides protection; wires inside may need separate strain relief inside the enclosure. |

| Typical Use | Direct cable runs into equipment. | Conduit-protected wire/cable runs terminating at equipment. |

Conclusion:

While both cable glands and conduit glands are crucial for terminating electrical connections safely and securely, they are fundamentally different components designed for distinct tasks. Cable glands clamp and seal cables. Conduit glands clamp and seal conduit pipes. Using the correct type is essential for maintaining system integrity, safety, environmental protection, and compliance with electrical codes. Always select the appropriate gland based on the specific application (cable vs. conduit), the environment, and required certifications.

FAQ: Cable Glands vs. Conduit Glands

Q1: Can I use a cable gland instead of a conduit gland?

A: Generally No. A cable gland clamps onto a cable, not a conduit. It won't securely hold the conduit or properly seal the conduit-to-enclosure interface. Using one risks the conduit becoming loose and breaking the seal.

Q2: How to choose the right material for cable glands and conduit glands?

A: For cable glands, consider the cable's material, the environmental conditions (temperature, humidity, corrosion), and the required protection rating. For conduit glands, match the material with the conduit material and the installation environment to ensure compatibility and durability.

Q3: What are the installation precautions for cable glands and conduit glands?

A: When installing cable glands, ensure that the cable is properly positioned, the gland is tightened to the correct torque, and the seal is effective. For conduit glands, make sure the conduit sections are aligned correctly, and the gland is securely connected to prevent leaks and ensure the conduit system's stability.