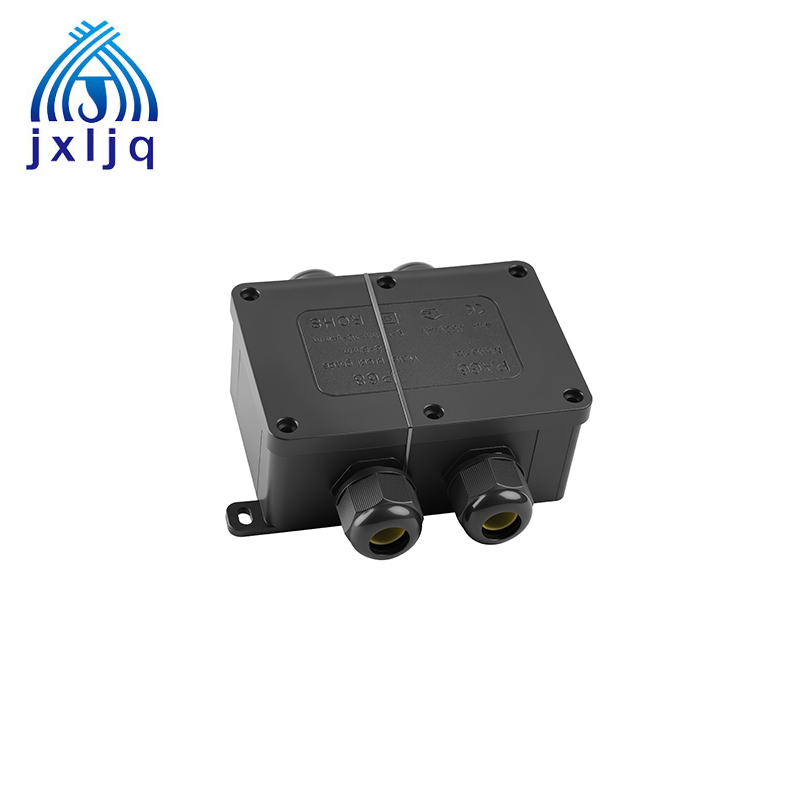

What Is A Junction Box?

A junction box is an essential electrical enclosure used to house wire connections safely. It protects electrical wiring from external damage, prevents accidental contact, and helps reduce the risk of electrical fires. Whether used in residential, commercial, or industrial settings, junction boxes ensure that wiring connections remain safe, organized, and compliant with electrical standards.

What Is a Junction Box?

A junction box is a protective container—usually made of metal or durable plastic—designed to hold and safeguard electrical wiring connections. Inside the box, multiple wires are joined together using connectors, terminals, or wire nuts. Its main role is to:

-

Protect electrical connections from moisture, dust, and accidental contact

-

Provide a safe environment for wiring splices

-

Keep wiring accessible for inspection, maintenance, or future expansion

-

Maintain a clean and organized electrical system

Junction boxes come in various shapes and sizes, such as square, rectangular, round, or waterproof outdoor types, depending on the installation environment.

Purpose and Function of a Junction Box

The primary purpose of a junction box is to ensure the safety and functionality of electrical connections. Its key functions include:

-

Protecting Electrical Connections: The enclosure shields wire splices and connections from dust, dirt, moisture, and other contaminants that could cause short circuits, electrical fires, or equipment failure. This protection is crucial in preventing electrical hazards and extending the lifespan of the electrical system.

-

Preventing Electrical Shocks: By containing exposed wires and connections, junction boxes reduce the risk of accidental contact with live electrical parts, which helps prevent electrical shocks to people or animals.

-

Organizing and Routing Wires: Junction boxes provide a neat and organized way to manage electrical wires. They allow multiple wires to be connected in one place, eliminating the need for messy and unprotected wire splices that can be difficult to trace or maintain.

-

Facilitating Maintenance and Repairs: Having all connections in a single enclosure makes it easier for electricians to inspect, troubleshoot, and repair the electrical system. If a problem occurs, they can quickly access the junction box to identify and fix the issue without having to dig through walls or ceilings.

-

Complying with Electrical Codes: Most electrical codes and standards require that all wire splices and connections be enclosed in a junction box. Using a junction box ensures that the electrical installation meets these safety regulations, avoiding potential fines and ensuring the safety of the building and its occupants.

How to Choose a Junction Box

Choosing the right junction box is critical to ensuring the safety and efficiency of your electrical system. Here are some key factors to consider:

-

Material: Select the material based on the installation environment. Plastic boxes are lightweight, affordable, and suitable for dry indoor areas. Metal boxes (aluminum or steel) are durable, fire-resistant, and ideal for commercial settings, wet locations (when properly sealed), or areas with high temperatures. Fiberglass boxes are corrosion-resistant, making them suitable for harsh environments like chemical plants or marine applications.

-

Size: The size of the junction box must be large enough to accommodate all the wires and connections without overcrowding. Electrical codes specify the minimum box volume required based on the number and gauge of wires. To determine the correct size, count the number of wires entering the box, and refer to the manufacturer’s specifications or local electrical codes for volume requirements.

-

Protection Rating (IP Rating): The Ingress Protection (IP) rating indicates the box’s resistance to dust and moisture. For indoor dry areas, an IP20 rating (protection against solid objects larger than 12mm) may be sufficient. For damp or wet locations, choose a box with a higher IP rating, such as IP65 (dust-tight and protected against low-pressure water jets) or IP67 (dust-tight and protected against temporary submersion).

-

Mounting Type: Consider how the box will be mounted. Options include surface-mounted (attached to the wall or ceiling), flush-mounted (recessed into the wall or ceiling), or ceiling-mounted. The mounting type depends on the installation location and aesthetic preferences.

-

Certifications: Ensure the junction box is certified by a recognized testing organization, such as Underwriters Laboratories (UL) in the United States or the International Electrotechnical Commission (IEC) internationally. Certification indicates that the box meets safety and performance standards.

Tips for Installing the Junction Box

Proper installation of a junction box is essential to ensure its safety and functionality. Follow these tips:

1. Turn Off the Power: Before starting any electrical work, always turn off the power to the circuit at the main electrical panel. Use a voltage tester to confirm that the power is off to avoid electrical shocks.

2. Choose the Right Location: Install the junction box in a easily accessible location for future maintenance. Avoid installing it in areas where it may be hidden behind furniture or appliances, or in locations prone to water damage (unless using a waterproof box).

3. Mount the Box Securely: Ensure the box is mounted firmly to a stud, joist, or other solid surface. For surface-mounted boxes, use screws or brackets that are appropriate for the wall or ceiling material. For flush-mounted boxes, cut a hole in the wall or ceiling that matches the size of the box and secure it in place with the provided clips or screws.

4. Prepare the Wires: Strip the ends of the wires to the appropriate length (usually ½ to ¾ inch) using wire strippers. Make sure the wire ends are clean and free of damage. Twist the exposed wire strands together tightly to form a secure connection.

5. Make Connections: Use wire nuts or terminal blocks to connect the wires. Ensure that all connections are tight and secure. For ground wires, connect them to the ground screw inside the junction box (if provided) or use a ground wire nut.

6. Secure the Wires: Use cable clamps or knockout seals to secure the wires where they enter and exit the junction box. This prevents the wires from being pulled or damaged.

7. Close the Box: Once all connections are made, attach the cover to the junction box using the provided screws. Ensure the cover is tight to prevent dust, moisture, or other contaminants from entering the box.

8. Test the Circuit: After installation, turn the power back on and test the circuit to ensure it is working properly. Use a voltage tester or a light fixture to verify that electricity is flowing correctly.

FAQ About Junction Boxes

Q: Can I install a junction box inside a wall without a cover?

A: No. Electrical codes require that all junction boxes have a cover to protect the connections from contaminants and prevent accidental contact with live wires. A missing cover is a safety hazard.

Q: How many wires can a junction box hold?

A: The number of wires depends on the size of the box and the gauge of the wires. Electrical codes specify the minimum volume per wire. For example, a 4x2x2.5-inch plastic box can typically hold 6-8 14-gauge wires. Always refer to the box’s specifications or local codes.

Q: Can I use a junction box outdoors?

A: Yes, but you must use a junction box rated for outdoor use with an appropriate IP rating (e.g., IP65 or higher). Outdoor boxes should also be weatherproof and resistant to UV rays.

Q: Is it necessary to ground a junction box?

A: Yes, if the junction box is metal. Metal boxes must be grounded to prevent electrical shocks in case of a short circuit. Plastic boxes do not require grounding, but the ground wires inside the box should still be connected properly.

Q: Can I splice wires without a junction box?

A: No. Electrical codes prohibit splicing wires without enclosing the splices in a junction box. Unenclosed splices are a fire hazard and can cause electrical shocks.