What are waterproof connectors?

In the realm of modern electronics and industrial applications, where exposure to moisture, liquids, and harsh environmental conditions is a common challenge, waterproof connectors have emerged as essential components. These specialized connectors are engineered to provide a secure and reliable electrical connection while preventing the ingress of water, dust, and other contaminants. This article will delve into the definition, working principles, common applications, key benefits, and Ingress Protection (IP) ratings of waterproof connectors.

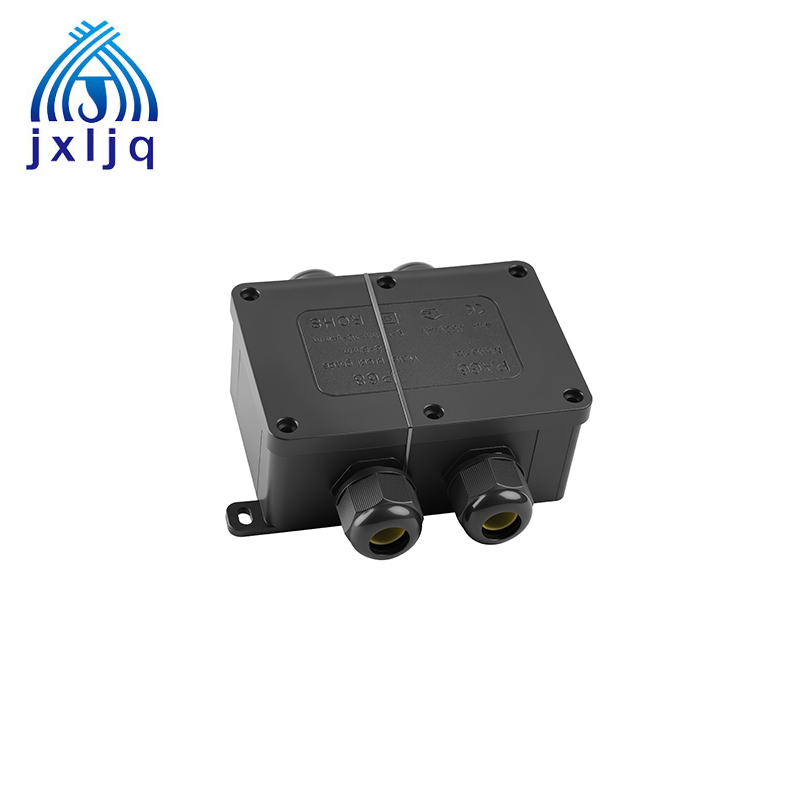

What are Waterproof Connectors?

Waterproof connectors, also known as water-resistant connectors, are electrical connectors designed to maintain their functionality and integrity in wet or damp environments. Unlike standard connectors, which are vulnerable to water damage, waterproof connectors are built with specific materials and designs that create a barrier against moisture. They are typically constructed using durable materials such as rubber, silicone, or thermoplastics, which offer excellent resistance to water penetration.

How Do Waterproof Connectors Work?

Unlike standard connectors, waterproof connectors incorporate specific design features and materials to create a barrier against moisture ingress:

1. Seals and Gaskets: The cornerstone of waterproofing. Elastomeric seals (typically made from silicone, rubber, or thermoplastic elastomers) are strategically placed:

Interface Seals: Between the plug and socket housing when mated.

Cable Glands/Seals: Where the cable enters the connector body, compressing around the cable jacket to prevent water tracking.

Pin Seals: Around individual pins/sockets within the connector body, preventing water migration along the contacts.

2. Sealed Housings: The connector body itself is designed with tight tolerances and robust materials (like rugged plastics, metals, or composites) to resist water penetration. Mating surfaces are precisely engineered.

3. Potting/Encapsulation: Some high-performance connectors, especially multi-pin types, are filled internally with a waterproof epoxy resin or silicone gel. This "potted" compound completely surrounds the internal connections and wires, blocking any potential pathways for water.

4. Locking Mechanisms: Secure mating mechanisms (screw threads, bayonet locks, latches) ensure the connector halves are tightly joined, compressing the interface seals effectively and preventing accidental disconnection that could expose contacts.

5. Material Selection: Resistant to corrosion (e.g., stainless steel contacts, brass or composite bodies) and degradation caused by UV exposure, chemicals, or extreme temperatures.

Common Applications

Waterproof connectors are indispensable wherever electronics meet moisture or harsh elements:

Marine & Offshore: Boats, yachts, shipboard systems, navigation lights, sonar, buoys, offshore platforms.

Automotive & Transportation: Under-hood components, sensors (ABS, fuel level), exterior lighting (LEDs), electric vehicles (battery connections, charging ports), trucks, buses, trains.

Outdoor Lighting: Street lights, landscape lighting, architectural lighting, signage.

Renewable Energy: Solar panel connections, wind turbine generators and controls, battery storage systems.

Medical Devices: Equipment requiring sterilization or used in wet environments.

Consumer Electronics: Outdoor cameras, drones, underwater lighting for pools, garden equipment.

Telecommunications: Outdoor cabinets, antenna connections, buried cable terminations.

Key Benefits

Waterproof connectors offer several key benefits over standard connectors, making them a preferred choice in many applications. Some of the key benefits include:

Reliability: By preventing the ingress of water, dust, and other contaminants, waterproof connectors help to ensure the reliable operation of electrical systems. This reduces the risk of electrical failures, short circuits, and other problems, which can lead to costly downtime and repairs.

Durability: Waterproof connectors are designed to withstand harsh environmental conditions, such as extreme temperatures, humidity, and vibrations. This makes them more durable and long-lasting than standard connectors, which are more prone to damage and wear.

Safety: In applications where water or moisture is present, there is a risk of electrical shock and other safety hazards. Waterproof connectors help to reduce this risk by providing a secure and reliable electrical connection that is protected from water ingress.

Versatility: Waterproof connectors are available in a wide range of sizes, shapes, and configurations, making them suitable for a variety of applications. They can be used to connect different types of electrical components, such as wires, cables, printed circuit boards, and sensors.

Common Waterproof IP Ratings for Connectors

| IP Rating | Solid Protection | Liquid Protection | Typical Use Cases |

|---|---|---|---|

| IP54 | Dust-protected (limited ingress) | Splash water from any direction | Indoor industrial, some outdoor enclosures |

| IP65 | Dust-tight | Low-pressure water jets | Outdoor equipment, washdown areas |

| IP66 | Dust-tight | Powerful water jets | Marine deck equipment, heavy industrial |

| IP67 | Dust-tight | Temporary immersion (1m/30min) | Automotive sensors, temporary submersion |

| IP68 | Dust-tight | Continuous immersion (mfr-specified depth/duration) | Underwater lights, submersible pumps |

| IP69K | Dust-tight | High-pressure, high-temp washdown | Food processing, sanitation-critical areas |

Conclusion

Waterproof connectors are far more than just "water-resistant" plugs and sockets. They are sophisticated engineering solutions combining specialized seals, robust materials, and precise manufacturing to create reliable electrical lifelines in environments where water and contaminants are constant threats. By understanding what they are, how they work, their diverse applications, key benefits, and the critical importance of IP ratings, engineers, technicians, and purchasers can select the right connectors to ensure safety, reliability, and longevity for their electronic systems operating in the most demanding conditions on Earth – and even underwater. Choosing the correct IP rating for the specific environmental challenge is paramount to achieving optimal performance.