What are the Types of Cable Gland

In the intricate world of electrical and instrumentation installations, ensuring safety, reliability, and longevity is paramount. A seemingly small but critically important component in achieving this is the Cable Gland. These unsung Cable Gland play a vital role in protecting connections and equipment from environmental hazards and maintaining system integrity.

1. What is a Cable Gland?

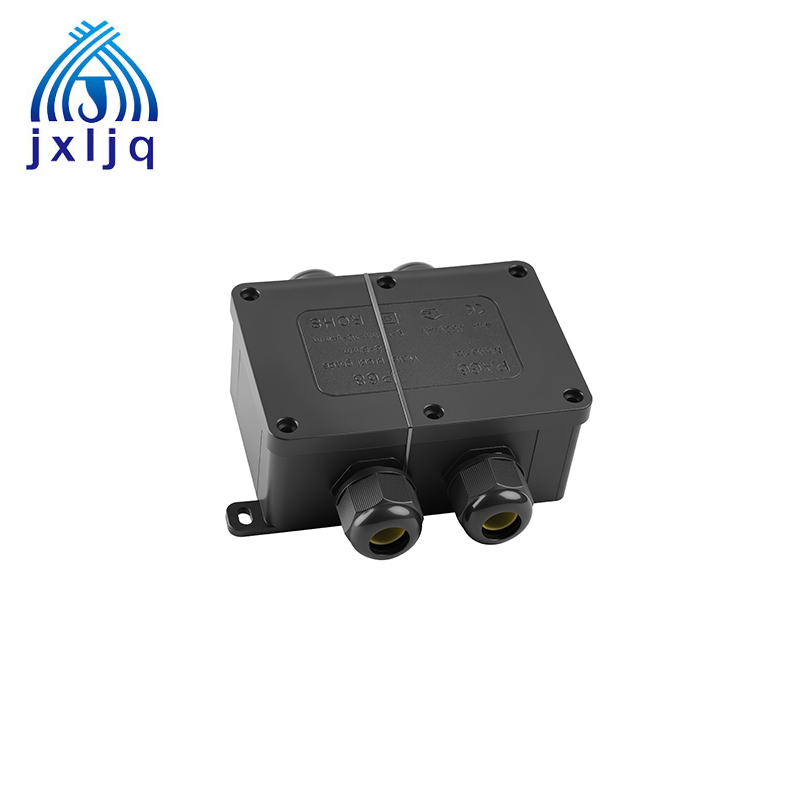

A cable gland, also known as a cable connector or cable fitting, is a mechanical device used to securely fasten and terminate cables at the entry points of electrical enclosures, machinery, or equipment. Its primary functions include providing strain relief to prevent cables from being pulled out, creating a environmental seal to protect against dust, water, moisture, and other contaminants, and in some cases, offering protection against explosive atmospheres. Cable glands are essential components in electrical and industrial installations to ensure the safety, reliability, and longevity of cable connections.

2. How Cable Glands are Constructed?

Materials

Cable glands are typically made from a variety of materials to suit different application environments. Common materials include:

Metal: Such as brass, stainless steel, and aluminum. Brass is widely used for its good mechanical properties and affordability. Stainless steel is preferred in harsh environments where corrosion resistance is crucial, like in marine or chemical industries. Aluminum is lightweight and suitable for some general industrial applications.

Plastic: Including nylon, polypropylene, and polyethylene. Plastic cable glands are often used in non-hazardous environments where weight reduction and cost-effectiveness are important. They are also resistant to certain chemicals and have good electrical insulation properties.

Structural Components

Body: The main housing that holds the other components and provides the mechanical support. It is designed to fit into the enclosure or equipment's cable entry hole.

Sealing Element: Usually made of rubber or elastomer, which creates a tight seal around the cable to prevent the ingress of contaminants. The sealing element can be in the form of a grommet, O-ring, or multiple sealing rings.

Locknut: Used to secure the cable gland to the enclosure. It is tightened against the enclosure's surface to ensure a firm installation.

Strain Relief Clamp: This component grips the cable outer sheath to provide strain relief, preventing the cable from being pulled or twisted at the entry point. It can be a separate part or integrated into the body of the cable gland.

3. Types of Cable Glands

By Application Purpose

Designed to offer a high level of water resistance. They are constructed with enhanced sealing elements and often have a higher IP (Ingress Protection) rating, typically IP65 or above. These glands are used in outdoor installations, such as street lighting, outdoor electrical cabinets, and applications where the cables are exposed to rain, water splashes, or even temporary submersion.

EMC cable glands are specially designed for electromagnetic compatibility, use quality materials and precise manufacturing to ensure signal stability and resist interference. Whether in industrial control, automation equipment or communications, they can provide reliable protection.

Specifically engineered for use in hazardous environments where there is a risk of explosive gas, vapor, or dust mixtures. They are designed to contain any internal explosion within the gland and prevent it from igniting the surrounding explosive atmosphere. Explosion-proof glands comply with international standards such as ATEX (Atmosphères Explosibles) in Europe or NEC (National Electrical Code) in the United States. They are widely used in industries like petrochemical, oil and gas, and mining.

The marine cable gland is made of corrosion-resistant materials and is tightly sealed, which can effectively resist seawater erosion and salt spray corrosion, ensuring stable and reliable power and signal transmission. It is a cable sealing device used to ensure the safety of cable connections in marine environments such as ships, marine engineering, and offshore oil platforms.

By Material

Metal Cable Glands: As mentioned earlier, metal glands offer high mechanical strength and durability. They are suitable for heavy-duty industrial applications where the glands may be subject to physical impact, vibration, or high temperatures. Brass glands are commonly used for general industrial purposes, while stainless steel glands are ideal for corrosive environments.

Plastic Cable Glands: Lightweight and cost-effective, plastic glands are often used in non-critical applications where the environmental conditions are not too harsh. They are also popular in applications where electrical insulation is required, such as in low-voltage electrical systems.

By Installation Method

Threaded Cable Glands: These glands have external threads on the body that mate with internal threads in the enclosure's cable entry hole. They are installed by screwing the gland into the enclosure and then tightening the locknut. Threaded glands are easy to install and provide a secure connection.

Push-fit or Snap-fit Cable Glands: Designed for quick and easy installation without the need for tools. The gland is simply pushed or snapped into the enclosure's hole, and the sealing and strain relief are achieved through the design of the gland's body and sealing elements. These glands are suitable for applications where rapid installation or frequent cable changes are required.

4. Selecting the Right Cable Gland

Choosing the correct gland involves considering:

Cable Type & Diameter: Unarmored, SWA, braid, screened? Exact outer diameter.

Material: Required corrosion resistance (brass, SS, plastic)?

Thread Type & Size: Must match the equipment entry.

IP Rating: Required level of dust/water protection (e.g., IP54, IP66, IP68).

Hazardous Area: Is ATEX/IECEx certification needed? What Zone and type of protection (Ex-d, Ex-e, etc.)?

Armor/Screen Clamping: Required for SWA/braid or EMC shielding?

Environmental Conditions: Temperature range, UV exposure, chemicals present?

Standards & Certifications: Required by the project or region (e.g., UL, CSA, IEC).

Conclusion

Far more than just a hole plug, the cable gland is a sophisticated engineered component fundamental to the safety, reliability, and performance of electrical and instrumentation systems across countless industries. Understanding the different types – from standard brass compression glands to complex stainless steel hazardous area variants – and selecting the right one based on cable type, environment, and protection requirements is crucial for any successful installation. By performing their critical functions of securing, sealing, and protecting, cable glands ensure that connections remain safe and operational, even in the most demanding conditions.