Understanding Cable Glands and Their Uses

In the realm of electrical and electronic systems, cable glands play a crucial yet often overlooked role. These unassuming components are vital for ensuring the safety, reliability, and longevity of cable installations in various industries. Whether in industrial settings, marine environments, or residential applications, cable glands are essential for managing and protecting cables. This article aims to provide a comprehensive understanding of cable glands, including what they are, their key functions and benefits, how they work, the materials used, the different types available, and how to install them.

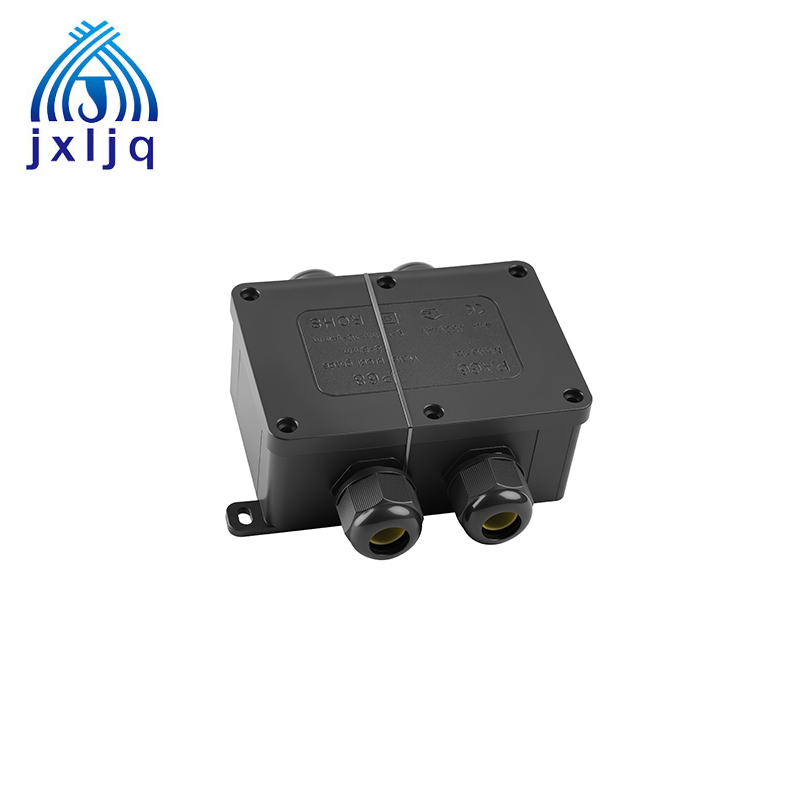

1. What Are Cable Glands?

A cable gland, also known as a cable connector or cable fitting, is a mechanical device used to terminate or connect cables to equipment, enclosures, or other components. It serves to secure the cable in place, provide environmental protection, and often offer electrical grounding or bonding. Cable glands are designed to accommodate different cable types, such as power cables, signal cables, and data cables, and can be used with both armored and non - armored cables.

2. Key Functions and Benefits of Cable Glands

Environmental Protection: Cable glands seal cables against ingress of water, dust, gases, and chemicals, safeguarding electrical systems from corrosion and short circuits.

Strain Relief: They anchor cables firmly, reducing stress on connections caused by movement, vibration, or pulling forces.

Hazard Mitigation: In explosive environments (e.g., mining or chemical plants), flameproof or explosion-proof cable glands prevent sparks from escaping, minimizing fire risks.

EMI/RFI Shielding: Some glands include shielding to protect against electromagnetic or radio frequency interference.

Versatility: Compatible with various cable types (armored, unarmored, braided) and sizes, they adapt to diverse applications.

3. How Do Cable Glands Work?

The working principle of a cable gland is based on creating a secure and sealed connection between the cable and the equipment or enclosure. The basic components of a cable gland typically include a body, a nut, a sealing element (such as a rubber or plastic grommet), and sometimes a grounding or bonding mechanism.

When installing a cable gland, the cable is inserted through the gland body. The nut is then tightened, which compresses the sealing element around the cable. The sealing element deforms to fit the shape of the cable, creating a tight seal that prevents the ingress of environmental contaminants. The body of the gland is usually threaded to fit into the equipment or enclosure, ensuring a secure mechanical connection.

In the case of armored cables, the gland may have additional components to grip the armor, such as a metal or plastic armor clamp. This clamp secures the armor of the cable, providing additional mechanical support and grounding if required. The grounding mechanism, if present, is usually connected to the gland body and then to the equipment's grounding system, ensuring a proper electrical connection.

4. Materials Used in Cable Glands

The materials used in cable glands are chosen based on the application requirements, such as the environmental conditions, the type of cable, and the mechanical and electrical properties needed. Some common materials used in cable glands include:

Plastics: Plastics such as nylon, polypropylene, and polyethylene are widely used in cable glands due to their lightweight, corrosion resistance, and relatively low cost. They are suitable for non - hazardous environments and for applications where electrical insulation is important.

Metals: Metals like brass, stainless steel, and aluminum are used in more demanding environments where higher mechanical strength, heat resistance, and resistance to corrosion are required. Brass is often plated with nickel or chrome for additional corrosion resistance, while stainless steel is highly resistant to corrosion in harsh environments such as marine or chemical plants.

Rubber and Elastomers: Rubber and elastomeric materials are used for the sealing elements in cable glands. They provide flexibility and elasticity, allowing them to form a tight seal around the cable. Materials such as neoprene, silicone, and EPDM (ethylene - propylene - diene monomer) are commonly used, depending on the temperature range, chemical resistance, and other environmental factors.

Composite Materials: In some cases, composite materials that combine the properties of different materials are used in cable glands. For example, a gland may have a plastic body with a metal insert for added strength, or a rubber sealing element with a reinforcing fabric for improved durability.

5. Types of Cable Glands

There are several types of cable glands available, each designed for specific applications and cable types. Some of the common types include:

Standard Cable Glands: These are the most basic type of cable glands, suitable for general - purpose applications. They are used with non - armored cables and provide basic environmental protection and mechanical support. Standard cable glands are available in different sizes to accommodate various cable diameters.

Armored Cable Glands: As the name suggests, these glands are designed for use with armored cables. They have a mechanism to grip the armor of the cable, such as a clamp or a set of teeth, to provide mechanical support and grounding. Armored cable glands are commonly used in industrial applications where the cable is exposed to high mechanical stress or where grounding is essential.

Weatherproof and Waterproof Cable Glands: These glands are designed to provide a high level of protection against water and moisture. They have a more robust sealing mechanism, such as multiple layers of rubber or a special design that prevents water from entering. Weatherproof and waterproof cable glands are used in outdoor applications, marine environments, and areas where the cable is likely to be exposed to rain, snow, or high humidity.

Explosion - Proof Cable Glands: In hazardous environments where there is a risk of explosive gases or vapors, explosion - proof cable glands are used. These glands are designed to prevent the ignition of the explosive mixture by ensuring that any electrical sparks or heat generated inside the equipment do not escape. They are constructed from materials that can withstand high pressures and are designed to meet specific industry standards for explosion protection.

High - Temperature Cable Glands: For applications where the cable is exposed to high temperatures, such as in industrial ovens, power plants, or automotive engines, high - temperature cable glands are used. These glands are made from materials that can withstand high temperatures, such as stainless steel or special high - temperature plastics, and the sealing elements are made from heat - resistant rubber or elastomers.

6. How to Install a Cable Gland

Proper installation ensures optimal performance:

Prepare the Cable: Strip the cable sheath to expose the inner cores and armor (if applicable).

Select the Correct Gland: Match the gland size to the cable diameter and verify its IP/EX rating for the environment.

Assemble the Gland: Slide the gland components (body, seal, locking nut) onto the cable in the correct order.

Secure the Cable: Tighten the gland body into the enclosure, compressing the seal and clamping the armor (if present).

Test the Seal: Conduct a pull test to confirm strain relief and inspect for gaps in the seal.

Always follow manufacturer guidelines and industry standards (e.g., IEC 62444) for compliance.

Conclusion

Cable glands are indispensable for ensuring safety, reliability, and longevity in electrical systems. By understanding their functions, materials, and installation requirements, engineers and technicians can select the right gland for any application—whether sealing a solar panel junction box or protecting offshore drilling equipment. As technology evolves, innovations in materials and design continue to expand their role in modern infrastructure.

Jixiang has efficient production capacity and is known as a professional supplier of cable glands. If you need high-quality cable gland, please contact us.

FAQ

Q1: Can cable glands be reused?

A: Ordinary type: If the seal of some plastic or metal glands is not damaged, they can be carefully disassembled and reused, but it is recommended to check the sealing performance regularly. Explosion-proof type: Usually a one-time installation, the integrity of the explosion-proof structure needs to be reconfirmed after disassembly, and non-professionals are not recommended to reuse.

Q2: Do cable glands require maintenance?

A: Regularly inspect for cracks, corrosion, or loose fittings. Replace worn seals or damaged components to maintain protection.

Q3: Can one gland handle multiple cables?

A: Multi-cable glands support 2–4 cables but require careful sealing. Single-cable glands are more common for reliability.