The Complete Guide for Solar Connectors

While solar panels and inverters grab the spotlight, the unsung heroes ensuring seamless, safe, and efficient energy flow within a photovoltaic (PV) system are the solar connectors. These small, specialized components are absolutely critical. This guide dives deep into everything you need to know.

What is a Solar Connector?

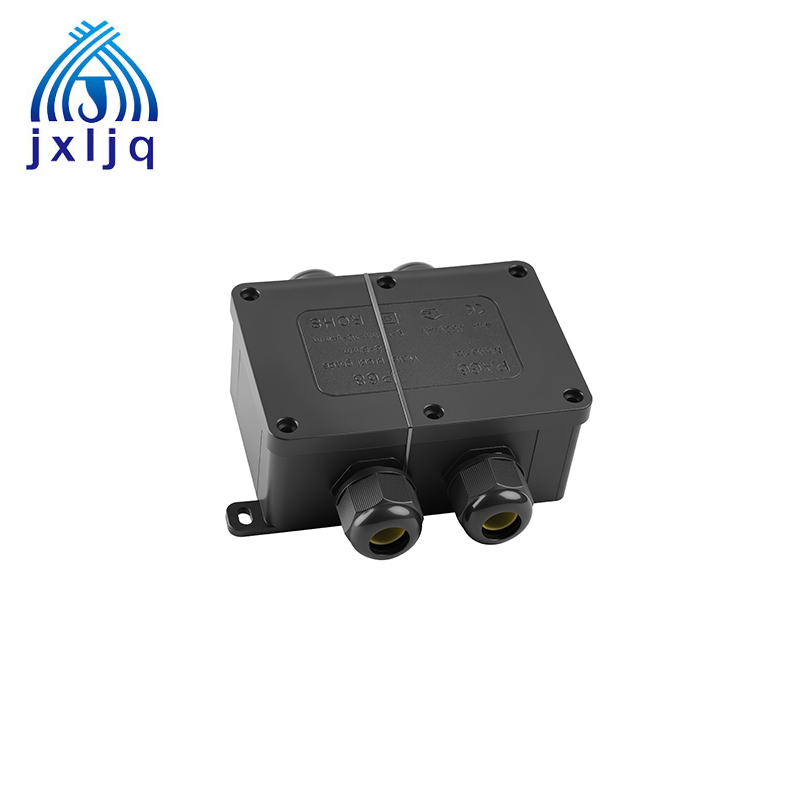

A solar connector is a specialized electrical plug and socket system designed exclusively for connecting solar panels and other components within a PV system. Think of them as the high-performance electrical "handshake" between modules, strings, combiners, charge controllers, and inverters. Unlike standard household plugs, they are engineered to:

-

Handle high DC voltages (up to 1500V) and currents (up to 50A+).

-

Withstand harsh outdoor environments (UV radiation, extreme temperatures, rain, snow, dust).

-

Provide a secure, low-resistance connection to minimize power loss.

-

Offer touch-safe protection when disconnected.

-

Prevent accidental disconnection due to wind or vibration.

-

Be highly durable for a system lifespan of 25+ years.

A Brief History of the Most Important Solar Connectors

1883–1950: PV technology emerged but remained niche until Bell Laboratories popularized it in the 1950s, driving demand for safe connectors.

1996: Multi-Contact (MC) invented the MC3 connector, named for its 3mm² contact pin, marking the first standardized solution for solar installations.

2004: The MC4 connector debuted as an upgrade to MC3, featuring a 4mm² contact pin, enhanced safety locks, and easier installation—quickly becoming the industry standard.

Why Are Solar Connectors So Important for Solar PV Systems?

Safety and Durability: Connectors lock wires securely, resisting UV radiation, moisture, and temperature fluctuations for decades. They reduce electrical arcing, a major fire hazard in loose connections.

Reduced Electrical Resistance: Properly crimped connectors minimize “hot spots” caused by loose wiring, preventing overheating and system inefficiencies.

System Longevity: High-quality connectors eliminate the need for frequent replacements, ensuring a PV system operates reliably for 25+ years.

How Are Solar Connectors Selected?

Choosing the right connector is vital. Key selection criteria include:

1. Certification & Compliance: MANDATORY. Look for connectors certified to international safety standards (UL 6703 in North America, TÜV 2PfG 1162/08.2007 in Europe, IEC 62852 globally). Never use uncertified connectors.

2. Voltage & Current Rating: Must exceed the maximum system voltage (e.g., 1000V, 1500V) and current (e.g., 20A, 30A, 50A) of the circuit they are used in.

3. Compatibility: Ensure compatibility between the connector brand/model on the panels and the cables/inverter you are using.

4. IP Rating: Indicates ingress protection against solids and liquids. IP67 (temporary submersion) or IP68 (continuous submersion) is standard for rooftop and ground-mount applications.

5. Cable Compatibility: Connectors must be compatible with the cross-sectional area (e.g., 4mm², 6mm²) and insulation type (typically PV-rated, halogen-free cable like TUV 2PfG 1169).

6. Quality & Brand Reputation: Stick with established, reputable manufacturers known for rigorous quality control and material durability.

7. Locking Mechanism: Ensure the locking mechanism (snap-lock, screw-lock) is secure, user-friendly, and reliable.

How Are Solar Connectors Used?

Proper installation is as critical as selecting the right connector:

1. Use the Correct Tools: Always use the manufacturer-recommended crimping tool and dies specifically designed for that connector brand and cable size. Generic tools cause poor crimps.

2. Prepare Cable Correctly: Strip the cable insulation precisely to the length specified by the connector manufacturer. Avoid nicking the conductor strands.

3. Precise Crimping: Crimp the metal contact onto the conductor with the calibrated tool. A good crimp is gas-tight and provides low electrical resistance. Visually inspect crimps.

4. Assemble Housing Correctly: Insert the crimped contact fully into the connector housing until it audibly clicks/locks. Ensure the sealing grommet (O-ring) is correctly seated and lubricated if specified by the manufacturer.

5. Secure Mating: Firmly push the male and female connectors together until the locking mechanism audibly clicks/snaps. Tug test the connection firmly to ensure it is fully seated and locked. Connectors should be "hand-tight" only; never use tools to force them together.

6. Strainage Loops: Form loops in cables below connection points to prevent water from running directly into the connector.

7. Avoid Strain: Secure cables to avoid mechanical strain on the connector bodies.

8. Inspect Regularly: Include visual checks of connectors (for cracks, discoloration, debris) as part of routine system maintenance.

Conclusion

Solar connectors are far more than simple plugs; they are precision-engineered safety and performance components fundamental to the success of any PV system. Understanding their history, importance, selection criteria, and proper installation is essential for installers, designers, and system owners alike. Adhering to certified standards, using compatible components from reputable manufacturers, and following meticulous installation practices ensures your solar array operates safely, reliably, and at peak efficiency for its entire lifespan. The humble connector truly is the linchpin of solar power.