How to Judge the Quality of Stainless Steel Cable Gland

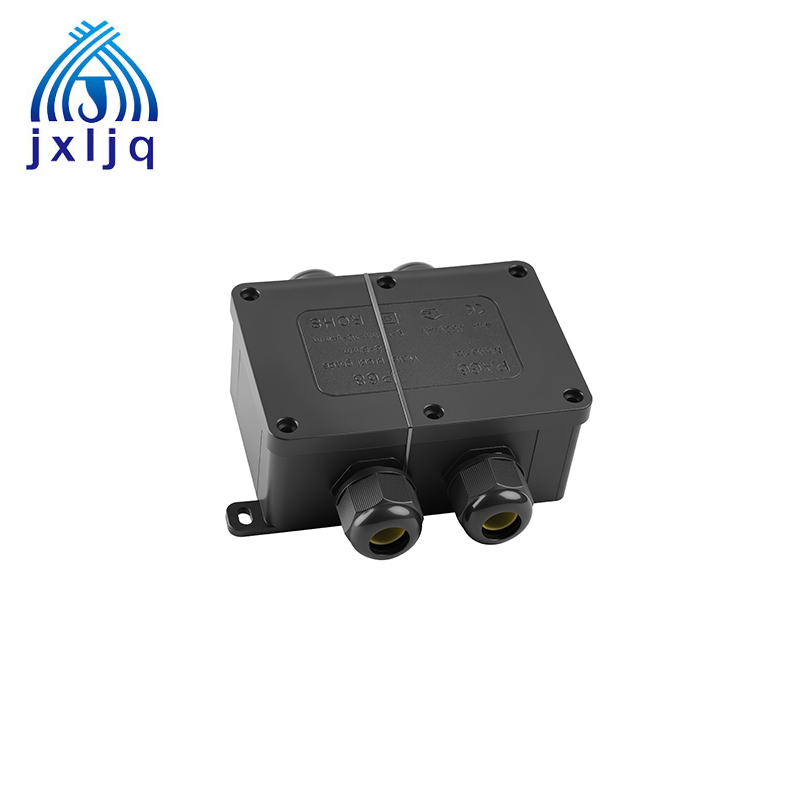

Stainless steel cable glands (also known as cable connectors, cable glands, or cable joints) are critical components for securing cables, providing environmental protection, and ensuring electrical safety in industrial applications. Evaluating their quality requires a systematic approach across four key dimensions:

1. Material and Grade

The base material and its grade determine core properties like corrosion resistance and durability.

Key Composition Traits

Chromium content (minimum 10.5%) forms a protective oxide layer, preventing rust.

Nickel enhances ductility, while molybdenum (in premium grades) boosts chemical resistance.

Common Grades

304 Stainless Steel: Ideal for indoor or mild outdoor use. Contains 18-20% chromium and 8-10.5% nickel, offering good general corrosion resistance.

316 Stainless Steel: Superior for harsh environments (marine, chemical plants). Includes 2-3% molybdenum, resisting saltwater, acids, and industrial pollutants.

Quality Checks

Look for clear grade markings or certifications from manufacturers.

Inspect for a smooth, uniform surface (no cracks, pits, or discoloration).

2. Environmental Protection

A high-quality gland must shield cables from contaminants and extreme conditions.

Sealing Performance

Tight seals prevent water, dust, and debris ingress, typically via rubber/silicone gaskets/O-rings (resistant to aging).

Check IP (Ingress Protection) ratings:

IP67: Dust-tight and water-resistant (temporary immersion).

IP68: Dust-tight and submersible for extended periods (top-tier protection).

Temperature Resistance

Stainless steel itself handles wide temperatures, but gaskets must match the application range:

High-temperature settings (e.g., industrial furnaces) require heat-resistant gaskets.

Low-temperature environments need gaskets that resist brittleness.

3. Application and Standards

Quality depends on alignment with use cases and industry benchmarks.

Application-Specific Design

Marine: Prioritize 316 stainless steel for saltwater resistance.

Hazardous areas (oil refineries): Choose explosion-proof glands to prevent spark ignition.

Compliance with Standards

IEC (International Electrotechnical Commission): Sets global electrical safety standards.

UL (Underwriters Laboratories): Validates safety for North American markets.

CE (Conformité Européenne): Ensures compliance with EU safety regulations.

4. Other Considerations

Additional factors that reflect quality:

Mechanical Strength: Robust construction (thick walls, strong threads) resists installation stress (tightening, pulling) without deformation.

Ease of Installation: Clear instructions and compatible components reduce errors, ensuring proper sealing and performance.

Manufacturer Reputation: Reputable brands use strict quality control and offer reliable customer support. Check reviews or industry recommendations.

Conclusion

When judging the quality of stainless steel cable glands, it is important to consider factors such as material grade, environmental friendliness, application and standards, and mechanical strength. 304 and 316 are suitable for different environments, and IP ratings can verify sealing properties.

If you need Cable Gland, please contact us.

FAQ

Q: What is the difference between 304 and 316 stainless steel cable glands?

A: The main difference is their corrosion resistance. 304 stainless steel is suitable for general environments, while 316, with the addition of molybdenum, offers better resistance to saltwater, chemicals, and harsh industrial environments.

Q: How do I know if a cable gland has good sealing performance?

A: Look for IP ratings. Higher IP ratings (such as IP67 or IP68) indicate better protection against dust and water. You can also check if the gaskets are made from high-quality, durable materials.

Q: Are explosion-proof cable glands necessary for all industrial applications?

A: No, only in hazardous environments where there is a risk of flammable gases, vapors, or dust. Explosion-proof cable glands are designed to prevent sparks from escaping and igniting the surrounding atmosphere.

Q: Can a stainless steel cable gland be reused?

A: It depends on the condition. If the gland is in good condition, with no damage to the threads, gaskets, or other components, it may be reused. However, it is important to inspect it carefully before reuse to ensure it can still provide adequate sealing and performance.