How to Find High Quality Brass Cable Gland?

In industrial electrical installations, the integrity of cable management directly impacts operational safety and equipment longevity. Among the critical components ensuring this integrity are brass cable glands—small yet vital devices that serve as the first line of defense against environmental hazards. This comprehensive guide will walk you through identifying high-quality brass cable glands, from understanding their fundamental role to practical inspection techniques.

What are Brass Cable Glands?

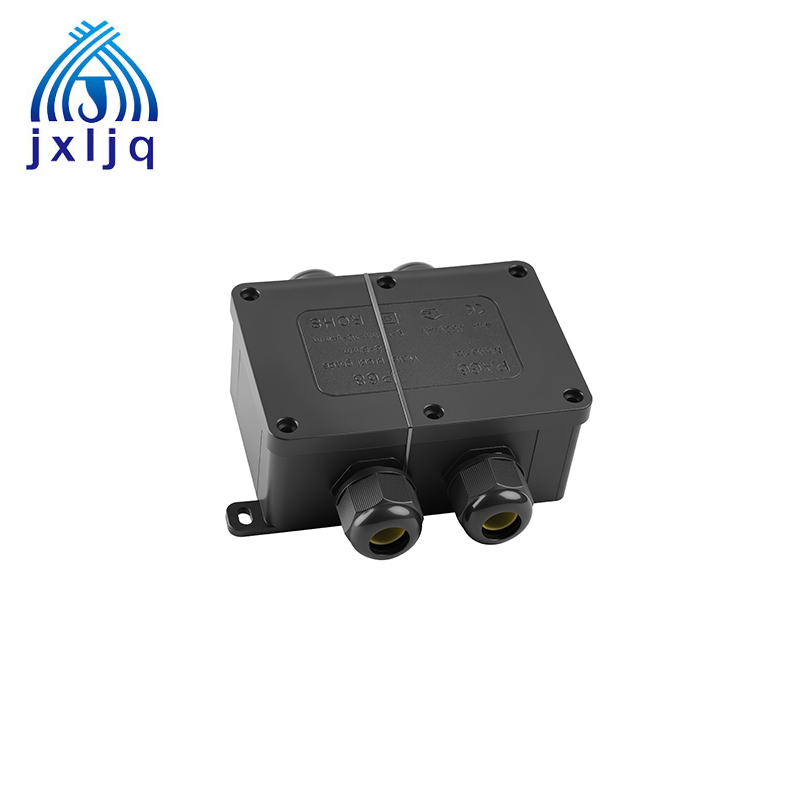

Brass cable glands are mechanical devices designed to secure and protect electrical cables where they enter enclosures or equipment. Constructed primarily from brass alloys conforming to standards like BS 6121 Part 1, these glands provide a robust seal that prevents ingress of dust, moisture, and other contaminants while maintaining electrical continuity.

The choice of brass as a core material offers distinct advantages: it combines excellent electrical conductivity with superior mechanical strength, making it ideal for both power and control cable applications. Compared to stainless steel alternatives, brass provides a more cost-effective solution for general industrial environments, while offering better corrosion resistance than plastic variants in moderate conditions. Its malleability allows for precise threading and tight tolerances, ensuring secure installations across diverse applications from manufacturing facilities to commercial buildings.

Key Steps to Finding a Quality Brass Cable Gland

1. Research Reputable Manufacturers

The foundation of quality begins with the manufacturer. Established brands with a proven track record are more likely to invest in consistent production processes and material sourcing. Look for manufacturers with at least a decade of industry experience, positive customer testimonials, and a demonstrated commitment to quality control.

A prime example is Jixiang, a respected name in cable management solutions. With years of specialized experience in brass forging, Jixiang has built its reputation on precision engineering and rigorous testing protocols. Their brass cable glands are designed to meet global standards, incorporating feedback from industrial electricians and maintenance professionals to ensure practical, reliable performance in real-world conditions.

2. Check for Quality Certifications

Genuine quality is validated through recognized certifications that confirm compliance with international standards. For brass cable glands, key certifications include:

ATEX and IECEx: Essential for hazardous environments where explosive atmospheres may exist, these certifications ensure the gland meets strict safety requirements for explosive atmospheres.

UL 514B: Indicates compliance with North American safety standards for electrical fittings in hazardous locations.

CE Marking: Confirms conformity with European health, safety, and environmental protection standards.

ISO 9001: Demonstrates a manufacturer's commitment to quality management systems.

Reputable manufacturers like Jixiang will prominently display their certifications, often providing access to certificate documents for verification. Always cross-check certification numbers with issuing bodies when possible.

3. Match the Gland to Your Cable & Application

A quality gland must perfectly suit both your cable specifications and environmental conditions. Consider:

Cable Dimensions: Verify that the gland's clamping range matches your cable's outer diameter, allowing for ±10% tolerance on installation torque as specified in industry standards.

Temperature Range: Standard brass glands typically operate between -40°C to +100°C, but confirm this matches your application's ambient conditions.

Environmental Factors: For corrosive environments (chemical plants, coastal areas) or high-moisture settings, consider enhanced protection options.

Special Requirements: Hazardous locations require ATEX/IECEx certified glands, while marine applications may need additional marine approvals like DNV or ABS.

4. Verify Key Features & Materials

High-quality brass cable glands share several defining characteristics:

Brass Purity: Look for glands manufactured from high-grade brass alloys with appropriate copper content (typically 57-65%) for optimal strength and corrosion resistance. Avoid glands with excessive impurities that can cause premature failure.

Sealing Mechanism: Ensure the gland features a robust sealing system—preferably double compression for critical applications—that maintains integrity across temperature cycles.

Thread Quality: Precision threading (metric, PG, or NPT) ensures proper mating with enclosures. Check that threads conform to relevant standards without burrs or deformities.

Pull-Out Resistance: The gland should maintain minimum pull-out forces: ≥160N for cables over 10mm diameter and ≥100N for smaller cables.

5. Consult Product Documentation

Thorough product documentation is a hallmark of quality manufacturers. Request and review:

Technical Datasheets: These should detail material composition, temperature ratings, clamping ranges, and certification information.

Installation Guidelines: Proper torque specifications, assembly instructions, and maintenance recommendations are essential for optimal performance.

Test Reports: Look for evidence of third-party testing verifying mechanical strength, sealing performance (IP ratings), and corrosion resistance.

Jixiang provides comprehensive documentation for their brass cable glands, including material certificates and performance test results, ensuring transparency and facilitating proper selection and installation.

6. Consider Nickel Plating

For enhanced durability in challenging environments, nickel-plated brass cable glands offer significant advantages:

Corrosion Resistance: The nickel layer (typically 5-10μm thick per BS 3382 standards) provides an additional barrier against moisture, chemicals, and salt spray.

Wear Resistance: Plating reduces galling during installation and improves longevity in high-vibration applications.

Aesthetic Appeal: Nickel plating provides a uniform, professional finish while making surface defects more visible during inspection.

Electroless nickel plating is particularly effective as it creates a uniform coating even on complex geometries like threaded surfaces. This option is highly recommended for outdoor installations, chemical plants, and marine environments where standard brass may face accelerated corrosion.

How to Inspect Defects in Your Brass Cable Glands

Even from reputable sources, a quick visual and physical inspection upon receipt is wise:

Check the Threading: Run your finger along the threads. They should be smooth, even, and free of burrs or cracks. Cross-threading can occur easily with poor-quality threads.

Look for Casting Imperfections: Inspect the body for visible porosity (small holes), cracks, or rough spots from the casting process.

Test the Seals: Ensure the sealing O-rings are present, fit snugly in their groove, and are made of soft, pliable material—not brittle or misshapen.

Assess the Finish: The surface should be uniform. For nickel-plated glands, check for flaking, discoloration, or uneven coating.

By following these guidelines and prioritizing quality throughout the selection process, you can ensure your brass cable glands provide reliable performance and long-term protection for your electrical installations. Remember that investing in quality components like Jixiang's brass cable glands ultimately reduces maintenance costs and enhances operational safety.

FAQ

Q: How do brass cable glands compare to stainless steel options?

A: Brass offers better electrical conductivity and cost-effectiveness for general applications. Stainless steel provides superior corrosion resistance in extreme environments but at a higher cost. Brass with nickel plating strikes a balance for moderately harsh conditions.

Q: What do IP ratings mean for cable glands?

A: IP (Ingress Protection) ratings indicate a gland's ability to prevent solid and liquid ingress. For example, IP68 offers complete dust protection and continuous submersion resistance, critical for outdoor or wet environments.

Q: Are brass cable glands suitable for outdoor use?

A: Yes, especially when nickel-plated. Their natural corrosion resistance makes them suitable for outdoor applications, though exposure to saltwater or heavy industrial pollution may require additional protection.

Q: How important is torque specification during installation?

A: Critical. Proper torque (typically with ±10% tolerance) ensures effective sealing without damaging threads or components. Always follow manufacturer guidelines.

Q: Can one cable gland fit multiple cable sizes?

A: Quality glands often cover a range of cable diameters through adjustable compression systems, but always verify the manufacturer's specified clamping range matches your cable size.