Demystifying Cable Gland Thread Types

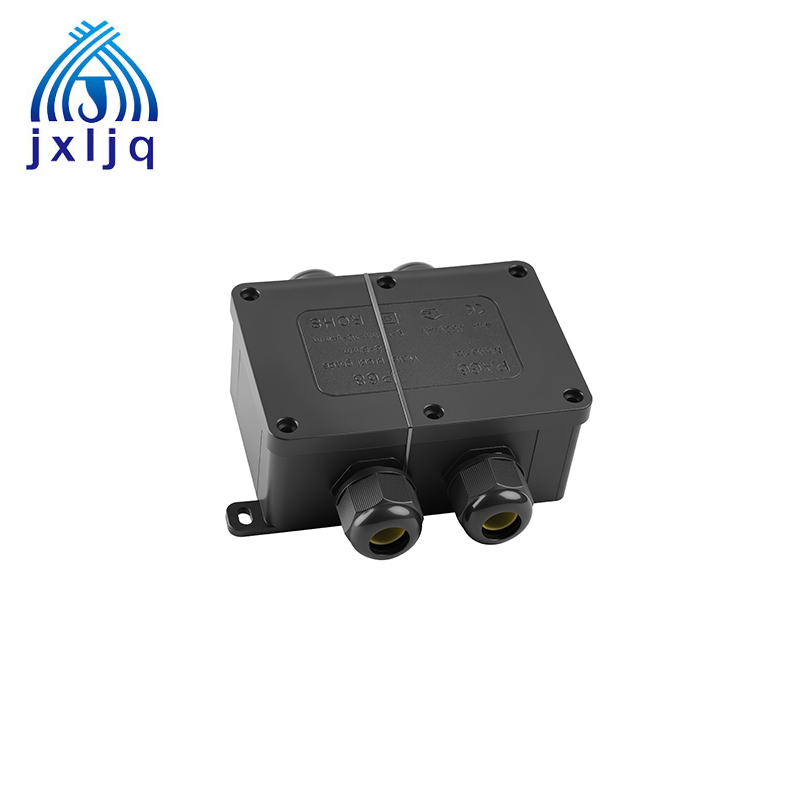

In the field of industrial connection, Cable Gland (cable sealing joint) is a key component to ensure the safe operation of equipment. The choice of its thread type directly affects the sealing performance, installation efficiency and system reliability. As a leading global supplier of cable management solutions, Jixiang provides precisely adapted industrial-grade sealing solutions for different scenarios based on the three core thread systems of NPT, Metric and PG. The following is an analysis of how Jixiang products empower industrial connections based on the technical characteristics and application scenarios of threads.

Thread Type

1. NPT (National Pipe Thread)

NPT (National Pipe Thread) is based on a 1/16 taper design. It forms a tight seal between liquid and gas through axial compression when the thread is tightened. It is the "sealing benchmark" in the US industrial standard. Its thread length is usually longer than Metric and PG, and is suitable for scenarios that need to resist the penetration of liquids, steam and gases. From the explosion-proof seal of petrochemical pipelines to the waterproof protection of food processing equipment, NPT threads have become the preferred solution for high-pressure and high-corrosion environments due to their self-sealing characteristics after torque is applied. Jixiang's NPT series products use multiple materials (stainless steel, nylon, etc.) and can adapt to different media and temperature conditions to ensure long-term stability in harsh scenarios such as shale gas extraction and ship engines.

2. Metric (metric thread)

Originated in Europe but becoming the "mandarin" of global industry, Metric thread uses millimeters to mark the major diameter and pitch (such as M20×1.5), and achieves seamless connection of cross-regional equipment with standardized parameters. In scenarios that require global adaptation, such as automated production lines and new energy equipment, Metric thread has become the standard for export equipment due to its versatility - whether it is control cabinet wiring in German factories or cable protection in Southeast Asian infrastructure projects, Jixiang's Metric series products can take into account sealing performance and installation efficiency through precise pitch design and surface treatment, helping multinational projects achieve "one-stop selection, global applicability".

3. PG (German Panzer-Gewinde)

As a representative of traditional German industry, PG (Panzer-Gewinde) threads achieve the characteristics of "small volume and high strength" with an 80° tooth angle and shallow tooth depth design. Compared with Metric's 60° tooth angle, it is more suitable for precision equipment with limited space. In scenarios such as rail transit signal cabinets and medical equipment cable connections, PG threads can meet mechanical strength requirements and reduce installation space with their compact structure of short teeth. Jixiang's PG series products have specially optimized thread tolerances to ensure that the connection stability can be maintained in a vibration environment, providing a "miniaturized" sealing solution for precision industrial equipment.

Jixiang's technical advantages

1. Full system thread coverage, breaking geographical restrictions

Jixiang products support three major thread systems: NPT, Metric, and PG. Customers do not need to change suppliers due to project regional differences. US local projects can use NPT threads to ensure compliance, global projects can rely on Metric threads to simplify the supply chain, and the European market can match local equipment standards through PG threads, truly realizing "one-stop procurement, full scene coverage".

2. Extended thread design to overcome complex installation problems

For scenarios that require penetration of equipment housings or multi-layer protective structures, Jixiang provides customized extended thread solutions to ensure installation depth by increasing the effective length of the thread, avoiding sealing failure caused by too short conventional threads. This design is particularly critical in scenarios that require penetrating installation, such as industrial control cabinets and marine engineering equipment.

Conclusion

In the context of industry and global manufacturing, the thread selection of Cable Gland is not only a technical issue, but also a key link in efficiency and cost control. Jixiang takes the three major thread systems as the cornerstone, combines material science and process innovation, and provides "precise adaptation, long-term and reliable" sealing solutions for energy, manufacturing, infrastructure and other fields.