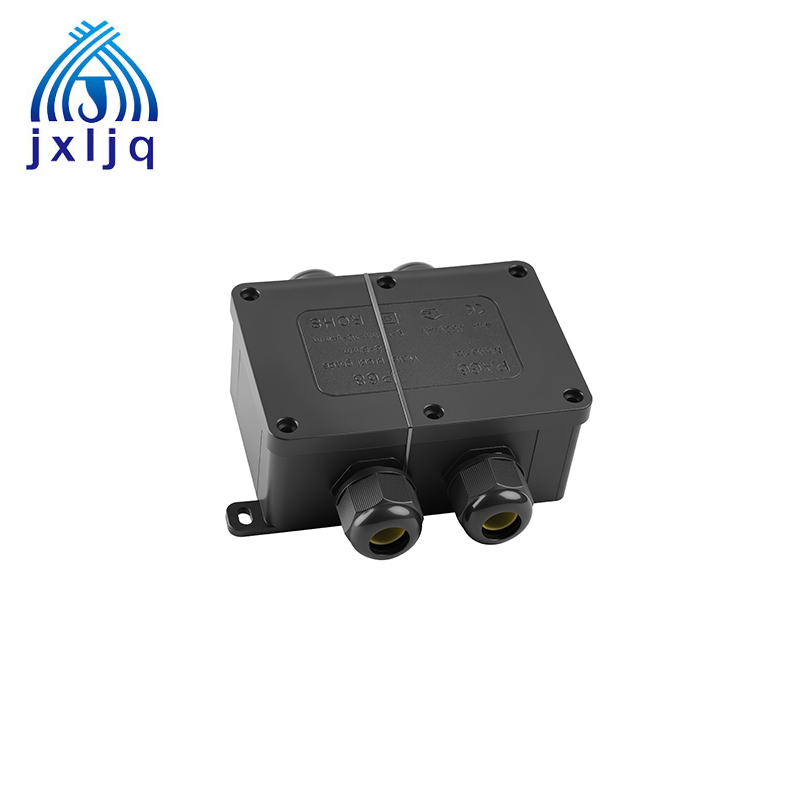

Cable Gland Thread Types and Their Purposes

In the fields of industrial automation, energy systems and equipment manufacturing, cable glands are key components to ensure the safety and sealing of electrical connections. Their core function is not only to fix cables, but also to achieve dustproof, waterproof, and anti-electromagnetic interference goals by adapting to different thread standards. However, in the face of complex application scenarios, how to choose mainstream thread types such as NPT, Metric, and PG? This article will explain their characteristics and selection logic for you.

The core role of cable connector threads

The thread type of the cable connector directly affects its compatibility with the equipment interface, sealing level and long-term stability. If the wrong type is selected, it will cause installation difficulties at best, and cause air leakage, water seepage or equipment damage at worst. Therefore, it is very important to understand the characteristics of different thread standards.

Analysis of mainstream thread types

1. NPT thread

Definition: NPT is an American standard tapered pipe thread, with a 60° thread angle and a 1:16 taper design, and sealing is achieved through interference fit between threads.

Core features:

Self-sealing: The tapered structure generates radial pressure when tightened, and no additional sealing ring is required.

High pressure tolerance: Suitable for gas and liquid high-pressure environments (such as oil pipelines and chemical equipment).

Application:

NPT threads in cable connectors are mainly used in applications that require a high level of sealing against liquids, gases or dust, especially in environments with pressure changes. It is commonly used in industries such as oil and gas where pipelines and equipment are exposed to harsh conditions, as well as industrial machinery where there may be a risk of liquid or gas infiltration. NPT threads are available in a variety of sizes, from small diameters for precision cables to large diameters for heavy industrial cables.

2. Metric thread

Definition: Metric is an internationally used metric straight thread, named "M+diameter+pitch" (such as M20×1.5), in accordance with ISO 228-1 standard.

Core features:

High degree of standardization: universally used and highly adaptable, especially in the European and Asian markets.

Sealing depends on accessories: O-rings, gaskets or lock nuts are required to achieve protection (IP rating).

Application: The purpose of using metric threads in cable connectors is to provide standardized and widely accepted connection options for various applications. They are commonly used in electrical and electronic equipment that require safe and reliable cable connections. Metric cable connectors with metric threads are often used in industries such as telecommunications that require large and stable cable connections, as well as general industrial applications that must be compatible with metric machinery and components.

3. PG thread

Definition: PG (Panzer-Gewinde) is a traditional German thread standard, represented by "PG+number" (such as PG13.5), with shallow threads and low cost.

Core features:

Easy to install: no precision machining required, suitable for quick assembly.

Limited protection: insufficient thread engagement depth, susceptible to vibration or humid environment.

Applications: PG threaded cable glands are commonly used in industries such as automotive, where cables are exposed to vibration, heat and humidity; and in marine applications, where harsh seawater environments may corrode and damage unprotected cables. PG threaded cable glands are also popular in industrial automation, where precise and reliable cable management is essential for the smooth operation of machinery and systems.

Factors to Choose the Right Thread Type

1. Application Environment

Harsh/Pressurized: NPT for tapered, leak-proof seals.

Standard Industrial: Metric for universal metric compatibility.

Vibration/Corrosion: PG for superior mechanical and environmental protection.

2. Compatibility

Match gland threads to mating fittings (e.g., NPT for North American equipment, PG for European automotive systems).

Avoid mismatches that cause installation failures or sealing gaps.

3. Cable Specs

Diameter: Ensure thread size range fits cable outer diameter (check manufacturer size charts).

Type: Armored/stiff cables need threads with strong grip (e.g., PG's serrated profile).

4. Industry Standards

Oil & Gas: NPT dominates for pipeline and rig connections.

Telecom/Electronics: Metric threads for standardized component integration.

Automotive/Marine: PG threads as preferred European safety and performance standard.

Conclusion

Selecting the right thread type ensures your cable management system withstands environmental challenges, integrates seamlessly, and meets industry requirements. Prioritize sealing needs, compatibility, and cable type to avoid downtime and safety risks.

Jixiang is a professional cable connector supplier, which has been recognized by many well-known brands for its excellent quality and excellent service. Contact us today for expert guidance!