A Technical Guide About Cable Glands: What You Should Know

In modern electrical and industrial systems, ensuring the safety, integrity, and efficiency of cable connections is crucial. One of the essential components used to achieve this is the cable gland. Although small in size, cable glands play a vital role in protecting cables, maintaining system reliability, and ensuring compliance with industry standards. This guide provides a detailed overview of what cable glands are, their purpose, types, and how to choose the right one for your application.

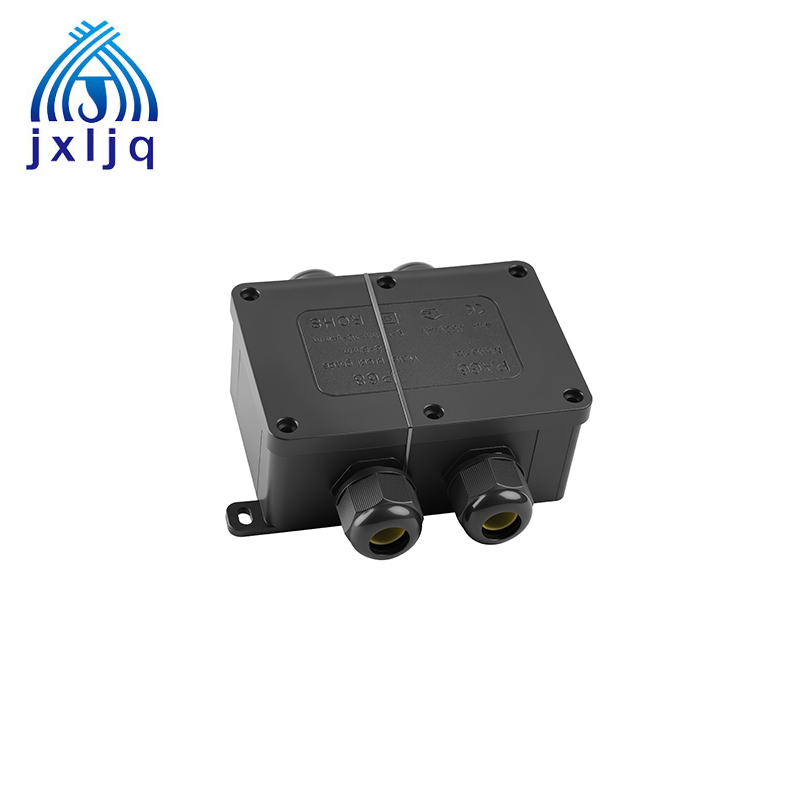

What Is a Cable Gland?

A cable gland—also known as a cable connector or fitting—is a mechanical device designed to secure the end of an electrical cable to equipment. It provides strain relief, seals the cable entry, and ensures that electrical connections are protected from external factors such as dust, moisture, and mechanical stress. Cable glands are used in a variety of applications, from industrial automation systems to marine and hazardous environments.

The Role of Cable Glands

Cable glands play multiple critical roles, proving they are more than just a simple "pass-through":

1. Strain Relief: This is their most basic function. The gland's mechanism grips the cable's outer sheath tightly, preventing the cable from being pulled out of the device due to external forces. This protects the internal electrical terminations from stress and damage.

2. Environmental Protection: Using built-in seals and compression fittings, cable glands prevent the ingress of dust, dirt, and moisture into the equipment. This is crucial for ensuring the long-term reliability of devices operating in harsh conditions.

3. Safety and Containment: In hazardous environments, cable glands are an integral part of the safety system. For instance, explosion-proof glands maintain the integrity of the equipment enclosure, preventing an internal explosion from propagating to the external hazardous atmosphere.

4. EMC Shielding: Specialized EMC cable glands provide a 360-degree connection between the cable's shield and the equipment housing. This effectively suppresses electromagnetic interference, ensuring signal integrity for data and control cables.

5. Cable Protection: They protect the cable insulation from being cut or abraded by the sharp edges of the entry hole in the enclosure.

When Should Cable Glands Be Utilized?

Cable glands should be used whenever a cable needs to enter a sealed or protected enclosure. Specific application scenarios include:

Outdoor Installations: To withstand rain, snow, dust, and UV exposure.

Wet or Dusty Environments: Such as food and beverage plants, car washes, and woodworking facilities.

Hazardous Areas: Like oil and gas refineries, petrol stations, mining, and grain processing plants where flammable gases or dusts are present.

Marine and Offshore Platforms: Environments facing high humidity, salt spray corrosion, and constant vibration.

Machinery and Automated Production Lines: Where exposure to oils, coolants, and physical vibration is common.

Data and Communication Rooms: Where EMC shielding is required to prevent signal interference.

Types of Cable Glands

1. Waterproof Cable Gland

Waterproof cable glands are designed with sealing rings to prevent water ingress, providing protection ratings such as IP66, IP67, or IP68. They are ideal for outdoor, marine, and industrial applications where exposure to rain, moisture, or splashing water is common.

2. EMC Cable Gland

EMC (Electromagnetic Compatibility) cable glands are used to ensure proper shielding of cables and prevent electromagnetic interference (EMI). These glands maintain the electrical continuity between the cable screen and the gland body, ensuring system stability in sensitive electronic environments.

3. Explosion-proof Cable Gland

Explosion-proof or flameproof cable glands are built to contain sparks or flames within the equipment, preventing ignition in explosive atmospheres. They are widely used in oil and gas, chemical plants, and mining industries, complying with ATEX or IECEx certifications.

4. Marine Cable Gland

Marine cable glands are made from corrosion-resistant materials like brass or stainless steel to withstand saltwater and harsh marine conditions. They ensure reliable sealing and mechanical strength in shipbuilding, offshore, and port installations.

How To Choose Cable Glands?

Selecting the right cable gland depends on several key factors:

Cable Type and Diameter – Ensure the gland matches the outer diameter and construction of the cable.

Material – Choose from brass, stainless steel, aluminum, or plastic based on the environmental conditions.

Protection Rating (IP/IK) – Consider the required ingress protection for dust, water, and mechanical impact.

Application Environment – Use explosion-proof types for hazardous zones, waterproof types for outdoor use, and EMC types for shielded cables.

Thread Type – Match the gland thread (e.g., PG, NPT, or metric) to the enclosure entry specification.

By considering these factors, you can ensure a reliable and compliant cable installation that meets safety and performance standards.

Conclusion

Cable glands may appear to be simple components, but they are critical for ensuring electrical safety, performance, and protection in demanding environments. From waterproof to explosion-proof designs, each type serves a unique purpose in securing and sealing cable connections. Choosing the right cable gland not only extends the lifespan of your electrical system but also ensures compliance with industry regulations—making it an indispensable part of modern electrical engineering.